7 common procurement risks and how to mitigate them

- What are procurement risks?

- Why is procurement risk management important?

- 7 common procurement risks that could disrupt your supply chain

- The procurement risk management process

- Strategies to mitigate procurement risks

- Common pitfalls in procurement risk management

- Effective procurement management starts with effective procurement software

Procurement risks can disrupt the ability to obtain essential goods and services, leading to delays, budget overruns, and compliance issues. As global supply chains face new challenges from geopolitical tensions and economic uncertainty, effective risk management is more important than ever. By identifying threats early and putting controls in place, you can safeguard operations and maintain business continuity.

This guide covers common procurement risks, a structured risk management process, and practical strategies to protect your business.

What are procurement risks?

Procurement risk

Procurement risk is the possibility that something will disrupt your ability to get the goods and services your business needs. These risks range from supplier failures and price changes to quality problems and compliance violations, any of which can throw off procurement goals.

When these risks become reality, the effects can hurt your business. Production might stop because of missing parts, profit margins can shrink when costs suddenly increase, or customer relationships may suffer if you can't deliver orders on time.

In serious cases, procurement failures can lead to regulatory fines, lawsuits, or reputation damage, especially when safety or ethical issues are involved.

The COVID-19 pandemic exposed many procurement weaknesses, such as limited supply chain visibility that made it difficult to track inventory globally, overreliance on single suppliers that suddenly shut down, and shipping problems caused by closed ports and transportation restrictions.

Other events—like cyberattacks on key suppliers, natural disasters in manufacturing regions, and sudden tariffs from trade disputes—have made procurement risk management essential for every business.

Why is procurement risk management important?

Proactive procurement risk management protects the company's financial health and keeps operations running smoothly. When risks go unmanaged, the bottom line can be affected by consequences such as production shutdowns, contract penalties, or lost sales opportunities.

Here are the key benefits of managing procurement risk effectively:

- Cost savings and financial stability: Avoid emergency sourcing costs by planning ahead. You can do this by negotiating better terms with secondary suppliers and consolidating purchases for volume discounts and lower total costs.Improved supplier relationships: Set clear expectations and foster transparency with vendors. Collaborate on risk mitigation and contingency plans while building long-term, strategic partnerships instead of one-off transactions.

- Enhanced business continuity: Stay operational when competitors face disruptions. Identify weak links in your supply chain before they cause issues and use alternative sourcing and safety stock to reduce downtime.

Treating risk management as an ongoing process rather than a one-time project helps you stay ahead of problems instead of constantly reacting to them.

7 common procurement risks that could disrupt your supply chain

Different types of procurement risks can disrupt operations, inflate costs, and damage supplier relationships if not proactively managed. By understanding the nature of these risks—not just their outcomes—procurement teams can build smarter safeguards into their sourcing and supplier management strategies.

1. Poor vendor management

Procurement risk doesn’t end once a vendor is selected. Without active monitoring, performance reviews, and communication channels, suppliers may drift from expectations, ignore SLAs, or underperform over time. Poor vendor management can lead to recurring issues that go unnoticed until they escalate.

For example, take a manufacturing firm that relies on a long-time supplier for key materials but hasn't revisited performance metrics in over a year. If shipments begin arriving inconsistently or product quality starts slipping, the procurement team may not catch the trend until a critical deadline is missed—by which time remediation is more costly and complex.

2. Inadequate vendor sourcing

This risk involves selecting suppliers without adequate evaluation of their capabilities, stability, and compliance history. Often driven by a focus on cost alone, it opens the door to unreliable performance, quality failures, or reputational damage—especially when working with unfamiliar or overseas vendors.

For instance, let’s say the same manufacturing company selects a new overseas supplier because they offer a 10% cost reduction but skips due diligence on their labor practices or delivery performance. If that supplier struggles to meet demand or fails quality audits later on, the short-term savings could be outweighed by missed deadlines or customer dissatisfaction.

3. Misaligned procurement requirements

When internal teams don’t clearly communicate what’s needed—or when specifications are based on outdated assumptions—procurement may purchase the wrong items, incorrect quantities, or incomplete components. This disconnect often results in excess inventory, production delays, or the need for emergency reorders.

For instance, if a manufacturing company continues ordering raw materials based on an older version of its product design, it may receive components that no longer meet technical requirements. This could delay production while procurement rushes to source updated materials, increasing both cost and lead time.

4. Exposure to market volatility

Volatile input prices, shifting currency exchange rates, or sudden tariffs can all throw off cost forecasts. If contracts don’t include price protection mechanisms, or if the business relies too heavily on one geography or supplier, even minor shifts can significantly affect margins.

Let’s say the cost of a critical raw material spikes due to geopolitical unrest. If a manufacturing company hasn't secured pricing agreements or alternative suppliers, it could be forced to pay inflated rates or delay production—impacting profitability and delivery timelines.

5. Outdated procurement processes

Manual or outdated systems—such as spreadsheets, paper POs, or email-based approvals—slow down procurement and introduce unnecessary risk. These methods limit visibility, delay decisions, and increase the likelihood of data entry errors or misplaced documentation.

For example, if a procurement team at the same manufacturing company relies on a manual approval flow for large purchases, a lost form or delayed signature could hold up a critical order. Without automation, that delay could go unnoticed until production stalls due to a missing input.

6. Fragile supply chain design

Overreliance on a single supplier or region (or a lack of contingency planning) makes a business vulnerable to unexpected disruptions. Whether from natural disasters, shipping delays, or labor disputes, a fragile supply chain can bring operations to a halt.

Let’s say the same manufacturing company sources a key electronic component from one overseas vendor. If that region experiences a port strike or political unrest, the company could suddenly find itself unable to meet production targets—with no backup plan in place to fill the gap.

7. Unreliable forecasting and manual planning

Forecasting based on outdated sales data or “gut feel” introduces uncertainty into demand planning. When combined with manual order tracking or inventory reconciliation, this can lead to stockouts, overstocking, or invoicing errors—all of which affect cash flow and customer satisfaction.

For instance, let’s say your business uses spreadsheets to track demand and place orders. If actual sales dip but forecasts aren’t adjusted, the company may continue ordering materials at an inflated rate. Over time, this could tie up working capital in slow-moving stock and crowd out storage space for higher-priority inventory.

These risks rarely happen in isolation. They often overlap and compound, creating complex problems that require comprehensive management, not just quick fixes.

What is high-risk procurement?

High-risk procurement involves buying goods or services that could significantly affect your business operations if disrupted. This typically includes items that are critical to production, have limited supplier options, face regulatory scrutiny, or represent substantial financial commitments.

The procurement risk management process

Effective procurement risk management starts with identifying and assessing risks and becomes ongoing with constant monitoring. Here's how the process typically works:

- Find and evaluate potential risks: Complete a detailed risk review to spot possible problems and analyze how likely they are to happen and their potential effects

- Create mitigation plans: Design approaches to lessen or eliminate identified risks, such as working with multiple suppliers, strengthening contract oversight, and enhancing digital security measures

- Build reliable supplier connections: Cultivate meaningful partnerships with vendors to establish mutual trust, clear communication channels, and collaborative problem-solving

- Leverage digital solutions: Implement procurement platforms and digital tools to streamline operations, gain clearer insights, and strengthen overall risk oversight

- Set up monitoring processes: Establish clear methods to track risks, measure their consequences, and adapt as circumstances change

- Schedule ongoing evaluations: Consistently examine and refresh risk assessments and prevention tactics to maintain their effectiveness

A successful procurement risk management process identifies threats early, responds quickly, and continuously improves as new information becomes available.

Strategies to mitigate procurement risks

With understanding the procurement risk management process, the next part is to set up a defense strategy against procurement disruptions is a multi-layered approach. To remain resilient, combine complementary tactics to address risks from multiple angles, creating safeguards that prevent single points of failure.

1. Create consistency with structured workflows

Consistent procedures reduce risky variations. This includes clear approval workflows, vendor qualification criteria, and contract management protocols. Large companies might use comprehensive manuals and required training, while smaller businesses can start with checklists and standard operating procedures.

2. Minimize risk through automation

Automation reduces human error and speeds up processing. This can range from basic purchase order generation to advanced three-way matching systems that verify invoices against receipts and contracts. Small businesses can use cloud-based apps, while larger enterprises may integrate automation into their ERP systems.

3. Strengthen supplier partnerships proactively

Strong supplier partnerships provide early warnings and flexibility during disruptions. Regular communication, performance reviews, and collaborative planning are key. Focus relationship-building on strategic partners who provide critical components or services.

4. Use digital tools to centralize and control spend

Digital platforms centralize procurement data, enforce policy compliance, and provide analytics for better decisions. Mid-sized companies often benefit from SaaS platforms, while global enterprises may need custom solutions integrated with legacy systems.

5. Support technology adoption with in-context training

Making sure staff can use procurement automation tools effectively is essential. Digital adoption platforms offer contextual guidance, automated workflows, and just-in-time training. This approach works for businesses of any size, though complexity varies with the underlying systems.

Prioritize investments based on potential impact, cost, and readiness. Start by standardizing critical processes and addressing the most severe risks, then expand capabilities as resources allow.

Common pitfalls in procurement risk management

Even well-established companies make predictable mistakes when managing procurement risks. Being aware of common pitfalls will allow you to strengthen your approach and build more effective safeguards into procurement operations.

Many companies make the mistake of focusing only on price, ignoring the total cost of ownership. This narrow view overlooks quality, reliability, and service, factors that often determine the real cost of procurement decisions. Relying too heavily on single suppliers is another common mistake, creating dangerous vulnerabilities even when terms seem favorable.

Reactive risk management—addressing issues only after disruptions occur—keeps you in constant crisis mode. Without proactive identification and planning, the same preventable problems keep happening. Failing to document risk management processes also creates risky dependencies on key people who might leave.

Perhaps the biggest mistake is treating risk management as a one-time project. The procurement risk landscape constantly changes, with new suppliers, shifting regulations, and global challenges. If you don't continuously reassess risks, mitigation strategies quickly become outdated and ineffective.

Recognizing potential pitfalls is the first step toward better risk management. With awareness and planning, your procurement team can develop practices that prevent problems rather than simply responding to them.

Effective procurement management starts with effective procurement software

Effective procurement software provides visibility across all spending activities, allowing teams to monitor supplier performance, track compliance issues, and identify potential risks before they escalate. These tools centralize documentation, standardize approval workflows, and generate analytics that highlight spending patterns and anomalies.

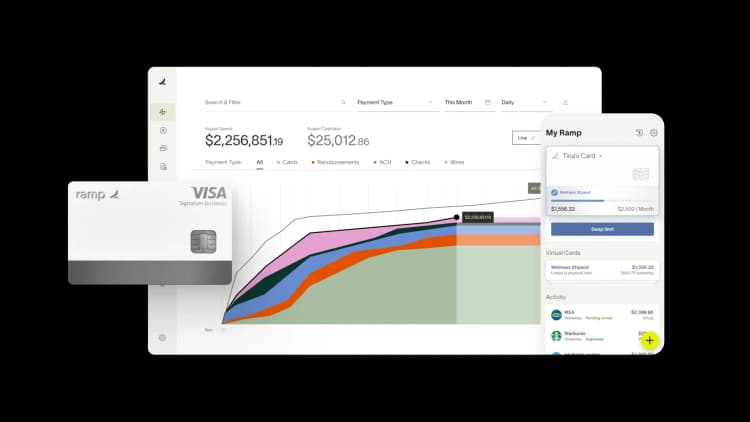

Ramp's procurement platform enhances procurement management through its integrated approach to spend control and supplier oversight. The software flags unusual spending patterns, enforces approval policies, and consolidates data in a single interface, giving teams immediate insight into their procurement processes.

Learn more about how Ramp Procurement can enhance your procurement management strategies.

Don't miss these

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Compared to our previous vendor, Ramp gave us true transaction-level granularity, making it possible for me to audit thousands of transactions in record time.”

Lisa Norris

Director of Compliance & Privacy Officer, ABB Optical

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°