What is single source procurement? Benefits and challenges

- What is single source procurement?

- Why is single sourcing in procurement important?

- What are the benefits of single source procurement?

- Challenges of single source procurement

- The risks of single source procurement

- Single sourcing vs. sole sourcing

- How to implement a single source procurement strategy

- Use Ramp to enhance your procurement process

Single source procurement means working with just one supplier for a specific product or service, even when you have other options. By choosing one vendor, you can better control quality and develop solutions tailored to your business needs. It's a strategy that focuses accountability and builds stronger supplier relationships, but it can also increase supply chain risk.

This guide covers the benefits and challenges of single sourcing, how to implement it, and how it compares to other procurement approaches.

What is single source procurement?

Single source procurement

Single source procurement, also called single sourcing, is when you choose to buy a specific product or service from just one vendor, even though other capable suppliers exist.

This differs from sole sourcing, which happens when only one supplier can meet your requirements.

You might choose single source procurement based on:

- How important the item is to the business, especially for critical components

- How reliable the supplier is, based on consistent performance and financial stability

- Special capabilities like proprietary technology, unique expertise, or exceptional quality

Single source procurement can be applied across many industries and categories. Whether you're buying raw materials, component parts, professional services, or technology solutions, this approach makes sense when deeper supplier integration matters more than having multiple suppliers.

Why is single sourcing in procurement important?

Single source procurement shapes the entire supply chain. By focusing purchasing with one supplier, you create effects that influence supplier integration, inventory management, and long-term planning.

This focused approach helps sync production schedules, align quality systems, and coordinate technology roadmaps that support business goals. These bring in benefits such as:

- More efficient communication through established channels and familiar contacts

- Tailored support, like dedicated account teams and customized ordering systems

- Specialized technical help and joint innovation, as suppliers better understand your challenges

Unlike multiple sourcing, which spreads purchases across several vendors and dual sourcing, which maintains two suppliers to reduce risk, single source procurement focuses resources on one relationship.

It works best when consistency matters most, like manufacturing precision components or delivering complex services. Industries such as aerospace or pharmaceuticals often benefit from single sourcing for critical inputs, where quality and reliability outweigh the risk of supply disruption.

What are the benefits of single source procurement?

Single sourcing centralizes spend with a single vendor, which can lead to stronger negotiating leverage, tighter operational alignment, and more consistent delivery performance. Let’s take a deeper look into why single sourcing is beneficial:

Cost efficiency

Single source procurement drives cost efficiency beyond just lower unit prices. Managing one supplier relationship instead of many reduces staff time, paperwork, and system maintenance. Logistics become simpler and less expensive with standardized shipping, consolidated deliveries, and optimized inventory levels.

Improved negotiations

With single source procurement, you gain leverage for better pricing and contract terms by concentrating purchasing volume. When you become a significant customer to one supplier—rather than a minor account with many—you get priority status and tangible benefits.

Suppliers often offer volume discounts, better pricing, or more favorable payment terms. Contract negotiations become more productive, as suppliers are willing to customize terms for a substantial, long-term relationship.

Enhanced product consistency

Consistent output is a key advantage of single source procurement that directly affects your brand reputation and customer satisfaction. When your products or components come from a single source, you minimize variations in materials, manufacturing processes, and quality standards. This ensures reliable product performance, consistent adherence to specifications, and satisfied customer expectations.

Higher-quality goods and services

Deeper supplier engagement naturally improves quality. Suppliers develop a thorough understanding of your specifications, processes, and expectations through repeated business.

This familiarity allows suppliers to suggest process improvements, identify potential issues early, and customize offerings to better meet your specific needs. Over time, suppliers become extensions of your quality system, resulting in fewer defects, more consistent performance, and ongoing improvement.

Market advantage

Single source procurement can create meaningful competitive differentiation for your business. You may gain exclusive access to supplier innovations and specialized technologies and premium service levels unavailable to competitors using multiple sources.

This exclusivity can lead to faster product development cycles, unique product features, and superior customer service capabilities. In fast-moving industries, the accelerated innovation and responsiveness enabled by close supplier collaboration often outweighs the potential cost savings of competitive bidding.

Streamlined operations

Operational simplicity is one of single sourcing's most practical benefits. Supply chain coordination becomes more straightforward with fewer moving parts and communication channels.

Focusing on one relationship reduces supplier management complexity, enabling faster responses to changes in demand, production schedules, or specifications, and quicker problem resolution, thanks to established relationships and clear accountability.

Challenges of single source procurement

While single sourcing offers many benefits, it also presents several challenges that can impact business operations and long-term strategic position.

Dependency risks

Relying on a single supplier makes your business vulnerable and can threaten operations. The business is exposed to supply disruptions caused by supplier production problems, transportation issues, and labor disputes.

Without alternatives, you'll struggle to resist sudden price increases. Disruptions can halt production, delay deliveries, or force costly emergency sourcing. This dependency is especially concerning for critical components or services where substitutes require major redesign.

Limited market perspective

Single source procurement can gradually isolate you from broader market developments. When you're not regularly engaging with multiple suppliers, your market awareness diminishes.

Downsides include:

- Missing alternative innovations or emerging technologies

- Losing negotiating leverage as switching costs increase

- Losing institutional knowledge about alternatives

This narrowed perspective can put you at a disadvantage if your competitors maintain broader supplier relationships and stay exposed to new ideas.

Potential for supplier complacency

Long-term, secure supplier relationships can sometimes breed complacency. Without competitive pressure, suppliers may become less motivated to offer competitive pricing or proactively suggest improvements. To counter this, you need comprehensive supplier performance management systems in place to keep them motivated.

Difficulty of switching suppliers

Changing single source suppliers can be challenging and may trap you in underperforming relationships. Transition costs often include requalification expenses, potential redesign requirements and duplicate inventory during changeover.

Operational disruptions during transitions can affect production schedules, product quality, and customer deliveries. You also risk losing knowledge, as the understanding built with the original supplier must be recreated with a new vendor. These barriers often lead companies to tolerate suboptimal performance rather than face the difficulties of switching suppliers.

The risks of single source procurement

Single sourcing may simplify procurement, but it concentrates risk. Without a backup, any disruption—natural disaster, supplier insolvency, or capacity issue—can quickly become your problem. Lack of competition also reduces leverage and can lead to:

- Volatile pricing and limited negotiation power

- Persistent quality issues with no easy point of comparison

How to manage the risk of single sourcing

- Build contingency plans: Don’t wait until a disruption forces your hand. A documented backup strategy ensures business continuity when your primary supplier can’t deliver.

- Monitor supplier risk on an ongoing basis: Risk profiles change—what was a stable supplier last year may not be today. Make supplier health reviews a regular part of your operations.

- Strengthen your contracts: Contracts should protect more than pricing—they should enforce accountability and safeguard operations if things go wrong.

- Keep long-term suppliers accountable: Even trusted partners can grow complacent. Regular performance reviews and structured improvement plans help keep standards high.

Single sourcing vs. sole sourcing

Sole sourcing happens when only one supplier can provide your required product or service due to unique specifications, proprietary technology, or exclusive market position. This differs fundamentally from single sourcing, where multiple capable suppliers exist but you choose to work with just one.

The decision-making process also differs:

- Sole sourcing is a constraint imposed by market conditions or technical requirements

- Single sourcing is a strategic choice to concentrate purchasing with one preferred supplier, even when alternatives exist

These approaches apply in different scenarios:

- Sole sourcing is typical for highly specialized equipment, proprietary software, or components for legacy systems, where the supplier market is limited by competition or intellectual property

- Single sourcing works best when standardization, quality consistency, or deep supplier collaboration offers strategic advantages

Here are the key differences between the two:

Criteria | Single source procurement | Sole sourcing |

|---|---|---|

Definition | Strategic choice to use one supplier among several capable options | Using one supplier because no viable alternatives exist |

Supplier availability | Multiple qualified suppliers available in the market | Only one supplier can meet requirements |

Risk profile | Moderate risk with mitigation options available | High risk with limited alternatives if problems occur |

Typical use cases | Complex components requiring consistency, strategic partnerships | Proprietary technology, patented products, unique services |

Dual sourcing offers a middle ground, maintaining two suppliers for the same item to balance risk mitigation with efficiency. This differs from multiple sourcing, which spreads purchases across several vendors to maximize competition but increases management complexity.

When choosing between these sourcing approaches, carefully evaluate market conditions, product criticality, and strategic objectives.

How to implement a single source procurement strategy

Establishing successful single source procurement requires careful planning and relationship management. Here’s how to build effective supplier partnerships while maintaining quality standards and minimizing the risks associated with relying on a single vendor.

1. Conduct a thorough evaluation of your supplier

Due diligence in supplier selection is the foundation of successful single source procurement. Before committing to one supplier for critical goods or services, you need to go beyond basic capabilities and pricing.

Key criteria for the assessment should include:

- Production capacity: Both current capacity and scalability for future growth

- Quality management systems: Certifications, process controls, and defect prevention

- Financial stability: Healthy balance sheets, sustainable growth, and adequate capitalization

- Cultural alignment: Communication style, problem-solving approaches, and business ethics

- Innovation capability: R&D investments, technical expertise, and continuous improvement

This in-depth evaluation is especially important for single sourcing, as the relationship will likely last for years and affect operations, quality, and competitiveness.

2. Develop strong contracts

Comprehensive, clearly defined contracts are essential for successful single-source relationships. These agreements should address all critical aspects to prevent misunderstandings, set performance expectations, and protect both parties' interests.

Well-crafted contracts are especially important in single source procurement, where switching suppliers isn't easy. Essential contract elements include:

- Detailed service level agreements (SLAs): Specifying performance metrics, quality standards, and delivery requirements

- Contingency plans for supply disruptions: Notification procedures, backup production options, inventory requirements

- Exit clauses for non-performance: Remediation processes, cure periods, transition support obligations

- Performance incentives: For exceptional service, innovation, or cost reduction

Contracts should balance protection with partnership, encouraging collaboration while providing recourse if performance issues arise.

3. Monitor performance continuously

Ongoing supplier management is critical with single source procurement. You need to identify and resolve problems quickly, since switching vendors isn't a simple option.

Proactive monitoring allows you to address small issues before they become major disruptions and maintain the high performance standards that justified the single-source decision. Best practices include establishing clear performance metrics, conducting regular reviews, and maintaining open communication channels at multiple organizational levels.

Effective KPIs to track include:

- Defect rates: Incoming inspection, during production, finished products

- On-time delivery percentages: Including complete and accurate documentation

- Responsiveness to issues: Acknowledgment time, resolution speed

- Compliance with contract terms: Pricing agreements, service level commitments

Performance feedback should flow in both directions. Suppliers should have opportunities to suggest improvements in processes or communication. Open communication at all levels—from executives to operational staff—ensures issues don't remain hidden and relationships stay healthy throughout the business.

By thoroughly evaluating suppliers, developing comprehensive contracts, and consistently monitoring performance, your business can create lasting partnerships that deliver quality, reliability, and value throughout the supply chain.

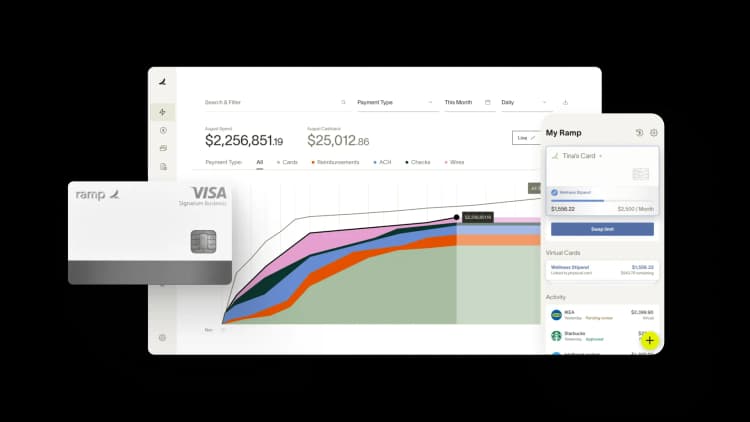

Use Ramp to enhance your procurement process

Procurement software streamlines procurement workflows by automating approval processes, centralizing supplier information, and providing real-time spending visibility. These solutions help businesses maintain compliance, reduce manual errors, and make data-driven decisions about their purchasing activities.

Ramp's procurement platform integrates purchase orders, approvals, and payments in one system, giving finance teams complete control over company spending. With customizable approval workflows, automated invoice matching, and comprehensive reporting capabilities, Ramp helps businesses optimize their procurement cycles while maintaining strong financial controls.

To boost your procurement management, Ramp:

- Streamlines procurement requests: Effortlessly intake procurement requests using AI that captures every detail, document, and contract fast

- Accelerates procurement cycles: Simplified workflows and automated approvals speed up purchasing timeframes, reducing delays and improving operational efficiency

- Increases spend visibility: Gain better insight into spending patterns, enabling more strategic supplier management and negotiations

- Works with all your existing tools: Approve requests directly in Slack, review contracts with Ironclad, and sync or import purchase orders with NetSuite, and more

Learn how Ramp's procurement software can automate your entire procurement process, from request to payment.

Don't miss these

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Compared to our previous vendor, Ramp gave us true transaction-level granularity, making it possible for me to audit thousands of transactions in record time.”

Lisa Norris

Director of Compliance & Privacy Officer, ABB Optical

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°