Purchase order process: Steps, flow, and examples

- What is a purchase order process?

- The purchase order process: Step by step

- Types of purchase orders

- Benefits of a structured purchase order process

- Common challenges and solutions

- Purchase order automation and technology

- Best practices for purchase order process management

- Ramp's all-in-one procurement software: Streamline your process

Imagine your team urgently needs new laptops, but three weeks later they’re still waiting because someone forgot to approve the request. Meanwhile, accounting is scrambling to understand why the budget doesn’t match actual spending. These frustrations often come from one missing piece: a clear purchase order process.

A purchase order process is the system your company uses to request, approve, and track purchases before any money is spent. When it works well, it prevents overspending, cuts delays, reduces maverick spending, and gives you visibility into every order from request to payment.

What is a purchase order process?

A purchase order process is the series of steps your company follows to request, approve, send, and document purchases from suppliers. It starts when someone identifies a need and ends when a vendor receives formal authorization to fulfill the order, creating a clear trail that protects both your business and your suppliers.

The PO process sits at the heart of procurement management. It links internal needs with external vendors while giving finance teams the visibility they need to track spending. A clear process helps prevent duplicate orders, flag unauthorized purchases, and maintain documentation for audits.

Key components of a purchase order

Every purchase order contains standard information that clarifies the transaction for both parties:

- PO number: A unique identifier used to track the order and match it with invoices

- Vendor details: The supplier’s name, address, and contact information

- Item descriptions: Details about what you’re ordering, such as product names, SKUs, or service descriptions

- Quantities: The number of units or amount of service being purchased

- Prices: Unit costs, subtotals, taxes, and the total amount your company agrees to pay

- Payment terms: When payment is due, accepted payment methods, and any early payment discounts

- Delivery information: Shipping address, expected delivery date, and any special handling instructions

- Terms and conditions: Details covering returns, warranties, liability, and dispute resolution

These elements work together to create a complete record of what you’re buying, from whom, and under what conditions. A purchase order becomes a legally binding contract once the vendor accepts it, giving both parties protection if disputes arise about pricing, quantities, or delivery terms.

Purchase order vs. purchase requisition

Purchase requisitions and purchase orders serve different purposes, though they’re sometimes confused. A purchase requisition is an internal document employees create when they need to buy something. It goes to managers or procurement teams for approval and explains what’s needed, why it’s needed, the estimated cost, and which budget will cover the expense.

A purchase order is the external document that goes to vendors after internal approval. It’s your official offer to buy goods or services under specific terms. Procurement teams or authorized buyers create POs based on approved requisitions.

The purchase order process: Step by step

The purchase order process moves a purchase from the initial need through final payment using a clear, repeatable sequence. Each step helps teams control spending, prevent errors, and keep orders moving without delays.

Step 1: Identifying the need

Departments identify purchasing needs when inventory runs low, equipment breaks, new projects begin, or seasonal demand increases. Employees closest to operations usually spot these needs first and confirm whether existing inventory, contracts, or vendor agreements can meet the requirement.

Documentation begins here. The requester records what’s needed, the business justification, estimated costs, and urgency. This information becomes the foundation for the requisition and helps approvers make informed decisions.

Step 2: Creating a purchase requisition

Employees who identify needs typically create purchase requisitions, though some organizations limit this to department heads or designated coordinators. Requisitions capture key details such as item descriptions, quantities, preferred vendors, budget codes, delivery dates, and the business reason for the purchase.

Requisitions move through an internal review process based on company approval workflows. Smaller purchases may require only a manager’s sign-off, while larger expenditures pass through additional approvers. For example:

- Less than $500: Manager review

- $500–1,000: Department head review

- $1,001–10,000: Finance manager review

- $10,001 or more: CFO review

Step 3: Vendor selection and quotation

Vendor selection involves evaluating multiple factors beyond price to secure the best overall value:

- Pricing and payment terms: Compare unit costs, discounts, payment schedules, and fees

- Quality and reliability: Review product specs, vendor reputation, references, and past vendor performance

- Delivery capabilities: Assess shipping timelines, coverage, and the ability to meet required dates

- Service and support: Consider warranty terms, return policies, technical support, and account management

Procurement teams request quotes from multiple vendors and compare them side by side. This often reveals opportunities to negotiate pricing, payment terms, or added services.

Step 4: Purchase order creation and approval

Once a vendor is selected, procurement converts the approved requisition into a formal purchase order. This involves transferring requisition details into a PO document and adding vendor-specific information, such as negotiated pricing, payment terms, and delivery instructions. The PO number links the PO back to the original requisition.

The PO then goes through its own approval workflow. Approvers verify budget availability, ensure pricing matches the quote, and confirm that terms align with company policies. Higher-value purchases may require sign-offs from senior leadership or finance directors.

Step 5: Sending the purchase order

Purchase orders can be sent through various channels depending on your systems and vendor preferences. Email is common, though many teams use procurement software to transmit POs electronically. Some vendors access POs through supplier portals, while others accept faxed or mailed copies.

Vendors must acknowledge receipt and acceptance of the PO. This confirmation creates the binding contract between both parties. Procurement teams track acknowledgment to identify any orders awaiting confirmation.

Step 6: Order fulfillment and receipt

Tracking begins as soon as vendors confirm orders. Procurement or receiving teams monitor shipment status, follow up on delays, and communicate timelines to requesters. Many organizations use tracking numbers to monitor shipments in real time.

When goods arrive, receiving teams verify quantities and inspect quality before acceptance. They check for damage, confirm that specifications match the PO, and document discrepancies. Three-way matching follows, comparing the PO, receiving report, and vendor invoice to ensure alignment before approving payment.

Step 7: Invoice processing and payment

Vendors send invoices after shipping, though timing varies. Accounts payable matches invoices against POs and receiving documents to catch errors, duplicate charges, or unauthorized additions. Any discrepancies are resolved with vendors before payment proceeds.

Payment processing follows company terms, such as net 30 or net 60. Some businesses take early payment discounts when available, while others optimize cash flow by paying closer to the due date. The accounting system records all transactions, maintaining a complete audit trail from requisition through payment.

Example of a complete PO process workflow

Here’s how these steps might play out in practice:

Sarah, a marketing manager, notices her team’s laptops are outdated and slowing down production work. She creates a requisition for five Dell laptops, including business justification, a preferred vendor, and a requested delivery date. The requisition routes to her director and then to finance for approval based on the company’s thresholds.

Procurement requests quotes from Dell, HP, and Lenovo. After comparing pricing, specifications, and warranty terms, Dell offers the best value at $1,950 per laptop for a total of $9,750.

Procurement creates a formal PO with the Dell quote details. Because the purchase exceeds $5,000, it requires approval from both Sarah’s director and the finance manager. Once approved, the PO is emailed to Dell’s representative, who confirms receipt and commits to a 10-business-day delivery window.

Nine days later, the laptops arrive. The receiving clerk inspects the shipment, verifies model numbers, and documents receipt. Dell sends an invoice for $9,750, and accounts payable performs a three-way match. With everything aligned, payment is scheduled under net 30 terms.

Types of purchase orders

Different purchase order types support different purchasing scenarios, from one-time buys to long-term vendor agreements. The table below summarizes when to use each type and what they’re best suited for.

| Purchase order type | When to use it | Key advantages |

|---|---|---|

| Standard purchase order | One-time purchases with clear quantities, pricing, and delivery dates | Straightforward transactions; all terms defined upfront; no ongoing obligations |

| Blanket purchase order | Recurring purchases over a set period, such as office supplies, cleaning services, or maintenance parts | Reduces administrative work; supports multiple releases; may secure better pricing through volume commitments |

| Contract purchase order | Long-term vendor relationships where quantities or delivery timelines aren’t fixed | Establishes pricing, quality standards, and service levels; avoids renegotiating terms for each order |

| Planned purchase order | Anticipated future needs where timing or quantities may shift | Helps forecast demand; gives vendors visibility; offers flexibility before details become binding |

A clear understanding of PO types helps you choose the right structure for each purchase and maintain strong vendor relationships.

Benefits of a structured purchase order process

A well-defined purchase order process strengthens both day-to-day operations and long-term financial performance by creating clarity, control, and consistency across every purchase.

- Cost control and budget management: Track spending against budgets in real time, prevent unauthorized purchases, and spot cost overruns early through approval workflows and spending limits

- Improved vendor relationships: Build trust with suppliers through clear agreements that set expectations, reduce misunderstandings, and support faster dispute resolution

- Better inventory management: Maintain optimal stock levels by tracking what’s been ordered, what’s arriving, and what’s in transit, helping you avoid stockouts or excess inventory

- Audit trail and compliance: Create complete documentation from request through payment, making audits easier and supporting regulatory requirements with organized, searchable records

- Reduced errors and disputes: Minimize invoice discrepancies, duplicate orders, and payment issues through standardized processes and three-way matching that catches problems early

- Enhanced spend visibility: Analyze purchasing patterns, identify opportunities to consolidate spend, negotiate stronger vendor terms, and make more informed procurement decisions

Common challenges and solutions

Even well-designed purchase order processes break down when steps are inconsistent or manual. The table below highlights the most common challenges, their root causes, and practical solutions:

| Challenge | Cause | Solution |

|---|---|---|

| Manual processing inefficiencies | Paper forms, email chains, and manual data entry slow down workflow and introduce errors | Centralize requests, approvals, and documents in one system to reduce delays and eliminate duplicate data entry |

| Approval bottlenecks | Approvers are unavailable, overwhelmed, or unclear about escalation paths | Standardize approval workflows so routing is predictable and automatically escalates when someone is unavailable |

| Lack of visibility into spending | No single source of truth for what’s been ordered, what’s pending, or its budget impact | Consolidate PO status, order history, and budget information in a shared dashboard accessible to requesters and approvers |

| Vendor management issues | Inconsistent evaluation criteria, undocumented agreements, and ad hoc communication | Strengthen vendor management with standardized evaluations, documented terms, and clearer communication channels |

| Compliance and audit concerns | Missing documentation or incomplete approval trails create gaps during audits | Ensure every purchase follows the same documented steps and store all supporting records in a centralized system |

| Resource strain | Too much administrative effort spent on low-value tasks | Reduce repetitive manual work so teams can focus on strategic procurement and supplier management |

Purchase order automation and technology

Purchase order automation replaces manual tasks with a consistent, rules-based workflow that routes requests, checks budgets, and tracks order status automatically. It speeds up approvals, reduces errors, and keeps every purchase aligned with policy, freeing teams to focus on higher-value procurement work.

When evaluating PO software, look for features that address your pain points and integrate with existing tools:

- Approval workflows: Configurable routing based on dollar thresholds, departments, or budget codes to ensure POs move to the right people

- Vendor management: A centralized supplier database with contract storage, performance tracking, and communication history

- Budget controls: Real-time budget checks that prevent overspending and flag potential issues before orders are placed

- Integration with existing systems: Connections to your ERP, accounting software, inventory management, and payment platforms to eliminate duplicate data entry

- Mobile access: Apps that let approvers review and authorize purchases anywhere, reducing delays when people are out of office

- Reporting and analytics: Dashboards showing spending patterns, vendor performance, cycle times, and opportunities for cost savings

How purchase order automation works

Workflow automation begins when employees submit purchase requests. The system routes each requisition to the right approvers based on rules like dollar thresholds, budgets, or item categories, escalating when someone is unavailable.

Approvals happen with a single click instead of email chains. Approvers see all relevant details, such as what’s being purchased, why it’s needed, the budget impact, and vendor information, in one place. Real-time tracking shows where each order stands. Requesters, procurement, and finance can monitor progress and budget impact, and automated notifications alert people when action is needed.

ROI of purchase order automation

Automation delivers fast savings. Tasks that once took hours, such as routing forms, chasing approvals, entering data, and matching invoices, now take minutes, cutting processing time by 50–70% in many organizations. Error reduction drives additional value: automated 3-way matching prevents overpayments, budget checks stop unauthorized spending, and duplicate detection avoids paying twice.

Using PO automation also compounds cycle-time gains. Faster invoice processing supports early-payment discounts, better visibility helps teams consolidate vendors and negotiate stronger pricing, and fewer rush orders reduce shipping and last-minute procurement costs. These combined benefits often let companies recover their software investment within six to 12 months.

Best practices for purchase order process management

Implementing consistent best practices strengthens control, improves visibility, and helps your purchase order process run more smoothly.

- Standardize PO templates and procedures: Create templates that include necessary fields, establish uniform procedures for each purchase type, and document workflows so everyone follows the same steps

- Set clear approval hierarchies and limits: Define who can approve purchases at different dollar thresholds, establish escalation paths for higher-value orders, and communicate authority levels across the organization to prevent confusion and delays

- Maintain accurate vendor databases: Keep supplier information current, including contact details, payment terms, and performance history, and regularly clean up duplicate or inactive vendor records

- Conduct regular process audits: Review your PO process quarterly to identify bottlenecks, gather feedback, and make adjustments based on performance metrics and user input

- Prioritize training and documentation: Provide training for employees who create requisitions, help approvers understand their responsibilities, and maintain updated guides to support consistent execution

- Track key performance metrics: Monitor cycle time from requisition to PO creation, approval turnaround times, invoice matching accuracy, and spending patterns to identify savings opportunities

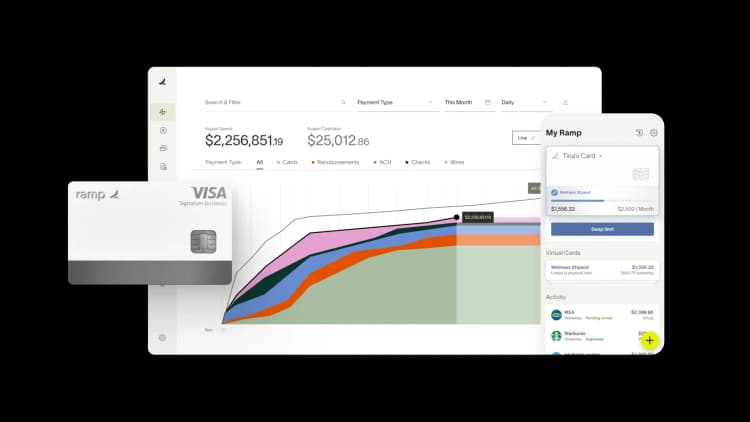

Ramp's all-in-one procurement software: Streamline your process

Ramp’s procurement software simplifies and automates the procure-to-pay process, helping you move faster and maintain stronger controls from request to payment.

With Ramp, you can:

- Intake in an instant: Drop a contract into Ramp’s procurement software, and its AI will parse the details and automatically complete the request

- Centralize communication: Route approvals, consolidate requests, and share documents in one place to improve transparency and reduce back-and-forth

- Know your committed spend: Automatically generate purchase orders for clearer visibility into upcoming invoices, while flagging discrepancies in units, prices, or totals

- Support risk mitigation: Protect against fraud and errors with automated three-way matching

- Get the best deals: Benchmark quotes against thousands of real, anonymized transactions to negotiate confidently and secure stronger pricing

- Integrate seamlessly: Connect Ramp with your ERP and finance systems to unify supplier data and eliminate manual work

Try Ramp Procurement to ensure compliance and improve overall productivity.

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Compared to our previous vendor, Ramp gave us true transaction-level granularity, making it possible for me to audit thousands of transactions in record time.”

Lisa Norris

Director of Compliance & Privacy Officer, ABB Optical

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°