How to reduce inventory cost by identifying cost creep

- What is inventory?

- What is cost creep and why is it important?

- How can I track my inventory cost creep?

- How to reduce inventory costs and save money by identifying cost creep

- How Ramp helps you track and control inventory cost creep

- Reduce inventory costs with Ramp

What is inventory?

The IRS generally defines inventory as any merchandise, raw materials, finished products, or supplies included as part of an item intended for sale. Let’s say you own a business that roasts and sells coffee. Your inventory could include green (or raw) coffee beans, roasted coffee beans, labeling, and the small bags that you fill with finished coffee beans. Essentially, inventory includes any materials you purchase that are intended to be included in a product for sale, even if they change form before the sale.

In the coffee example, the green coffee beans are still considered inventory even though they haven't been roasted yet. These beans are considered a raw material that'll be categorized into a “work in process” workflow and ultimately transformed into the wonderful, dark, nutty aroma we all know and love. And more obviously, the finished, roasted coffee beans that are sitting on your shelves and ready to sell to customers are also considered inventory. Your freshly roasted Arabica or Robusta coffee beans can be labeled as a “finished good” type of inventory.

What is cost creep and why is it important?

Cost creep is the steadily increasing cost per unit of an inventory component. Common causes include global supply chain constraints pushing ingredient and material costs higher and rising fuel prices increasing the cost of shipping and freight. These incremental cost increases might not be materially noticeable in a single month, but over time, can compound to cause a substantial impact to your bottom line.

The concept of inflation can also help us illustrate cost creep on a broader level. Inflation has risen dramatically over the last few years. Defined as the average rise in overall prices of goods and services throughout the economy, most businesses can probably attest that they have noticed some form of inflation on their overall costs. According to the Federal Reserve Bank of Minneapolis, the inflation rates over the past few years were:

● 8.0% in 2022

● 4.7% in 2021

● 1.2% in 2020

Essentially, this means the average prices of goods and services, including inventory costs, rose by 1.2% in 2020, another 4.7% in 2021, and an additional 8.0% in 2022.

What does this mean for your business? In short, if something costs you $1.00 at the beginning of 2020, and those costs increase by the inflation rate each year, you'll end up with goods that cost you $1.14 in 2022. Notice the calculation below:

$1.00 x (1.012 x 1.047 x 1.08) = $1.144

+14.4% increase from 2019 to 2022

By compounding these percentages together over a 3-year period, between 2019 and 2022, average prices for goods and services rose by about 14.4%. This means that if your inventory costs were $100 at the beginning of 2020, the same components would cost you $114.40 at the end of 2022.

Now, let’s put this into further context. If you were to keep your product sales prices stable, what would happen to your gross margin, or product profitability, over that same 3-year period, knowing that your inventory costs were steadily increasing?

Gross Margin = Sales - Cost of Goods Sold

Here's an example:

- In 2019, you sold a bag of high-quality coffee for $15. If it cost you $10 to make that coffee, bag it up, and hand it to the customer, your gross margin would be $5 or 33.3% ($15 - $10 = $5).

- Fast forward to 2022. You still sell that same bag of coffee for $15; however, now it costs you $11.44 to roast and bag that coffee you just sold, assuming 14.4% cost inflation (all else being equal). Your gross margin now is $3.56 per bag of coffee or 23.7% ($15 - $11.44 = $3.56).

- By simply paying for your inventory and roasting the way you have always done, your gross margins have decreased by -9.6% (33.3% - 23.7%).

Now think about the impact on a larger scale. If you had sold 1,000,000 bags of coffee beans, then you'd be leaving $1,440,000 in cash on the table simply from cost creep

($5 - $3.56) x 1,000,000 bags

How can I track my inventory cost creep?

For most businesses with a manageable list of cost inputs and inventory items, this process can be handled in a few simple ways. First, many accounting systems and Enterprise Resource Planning (ERP) software packages track inventory at the item level. Usually, if accounting is keeping up with accounts payable invoice entry at the item level, unit costs can be tracked relatively easily. Using Oracle NetSuite as an example, you can log in to the system, search for an inventory item or inventory component, click on the invoice history, and review each invoice and corresponding unit cost you have received over time for that particular item. Compare unit costs with this easy formula:

Unit Cost Inflation % = [ (Newest Unit Cost – Oldest Unit Cost) / (Oldest Unit Cost) ] x 100

This method is a very quick way to calculate the inflation creeping through your inventory costs. What if you don't have ERP software? Not to worry. Quantifying the impact of inflation and cost creep would be more manual, but still very doable. Either go into your inventory management system to export a list of all the invoices that show item-level detail and unit costs, or simply go into your files and find each one of your supplier or manufacturer bills the old-fashioned way.

The goal is to find or create a report that looks like Exhibit A. Notice that while the total invoice amount jumps around and can be inconsistent, the unit costs are steadily increasing. Now, use the data from Exhibit A to create a graph like Exhibit B, and you (or your leadership team) can visualize how cost increases have impacted the business.

Exhibit A

Exhibit B

How to reduce inventory costs and save money by identifying cost creep

1. Renegotiate lower prices with current suppliers.

If you have long-standing relationships with any suppliers, there's usually room to come back to the table to renegotiate. I've seen a lot of clients stay with vendors for five to ten years (or more) and never think to renegotiate prices on key inventory components. They assume a good relationship means a good price.

If you know you've consistently ordered higher volumes from a particular vendor or supplier over time, you can try to negotiate better economies of scale with the goal of decreasing the average cost per unit. Once you understand the impacts of cost creep, sometimes all it takes to protect your business is a phone call to talk pricing.

2. Shop around for new supplier discounts to lower costs of components, ingredients, or parts.

If renegotiating with current suppliers yields no cost-saving results, it might be time to search for a new supplier. Keep in mind that recipes and other intellectual property confidentiality agreements might limit your ability to easily find new suppliers.

However, if possible, it’s best to take advantage of even small opportunities to find a new supplier for a single component or ingredient. New suppliers often offer discounts to win your business, so stay diligent in this process. You might be surprised at how small wins can stack up into substantial material company cost savings.

3. Consider new freight, transportation, or logistics partners.

Traditionally, freight-in costs should be capitalized into inventory according to US Generally Accepted Accounting Principles (GAAP) and expensed through Cost of Goods Sold (COGS). While shipping and freight costs can be a more material inventory component in some businesses compared to others, it is an important area that I recommend companies investigate annually.

Global supply chain constraints in recent years have caused freight costs to increase in many countries, so it is best practice to investigate new freight brokers, systems, or logistics providers on an annual basis to make sure you are getting the best deal. Again, shop around. It never hurts to have a conversation.

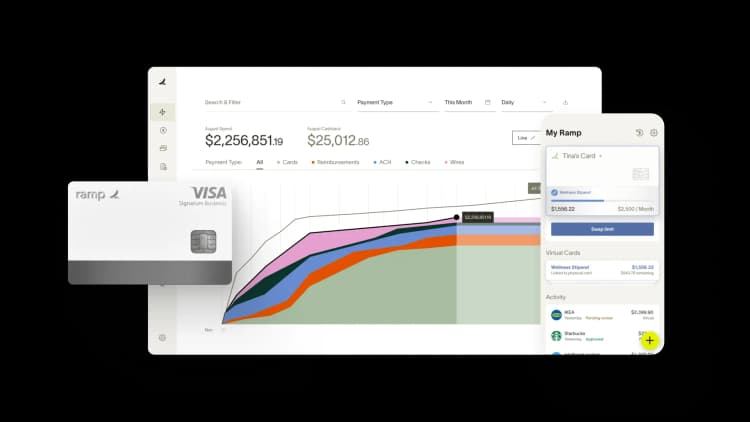

How Ramp helps you track and control inventory cost creep

Inventory cost creep happens when small, incremental price increases from suppliers go unnoticed, slowly eroding your margins over time. You might not catch that your regular supplier raised prices by 2% last quarter, or that shipping fees have quietly increased month over month. These seemingly minor changes compound quickly, especially when you're managing multiple vendors and thousands of SKUs.

Ramp's expense management platform gives you the visibility you need to spot these creeping costs before they impact your bottom line. When you use Ramp's corporate cards for inventory purchases, every transaction is automatically categorized and tracked in real time. You can set up custom spend controls that flag when a vendor's charges exceed historical averages or predetermined thresholds. For instance, if your packaging supplier typically charges $5,000 monthly but suddenly bills $5,500, Ramp immediately alerts your team to investigate the variance.

The platform's advanced analytics dashboard transforms your inventory spending data into actionable insights. You can compare costs across vendors, track price trends over time, and identify which suppliers consistently increase prices. This bird's-eye view makes it simple to renegotiate contracts or switch vendors when costs start creeping up. Plus, Ramp's automated receipt matching and expense categorization eliminate the manual work of tracking these changes in spreadsheets.

By centralizing all your inventory purchases through Ramp, you create a single source of truth for cost analysis. Finance teams can run reports showing year-over-year price changes by vendor or category, making it easy to spot patterns and take action. This proactive approach to cost management helps you maintain healthy margins and make informed decisions about your inventory strategy.

Reduce inventory costs with Ramp

Beyond tracking cost creep, Ramp streamlines your entire inventory expense workflow. The Ramp mobile app uses AI to capture and process receipts instantly—just snap a photo and you're done. Every transaction flows seamlessly into your accounting system with proper categorization, eliminating hours of manual data entry.

You can also set custom approval workflows that match your procurement process. Need manager sign-off for orders over $10,000? Want automatic approvals for trusted vendors under certain thresholds? Ramp lets you build these rules directly into your expense management system. This means faster processing for routine purchases while maintaining control over larger spending decisions.

With Ramp, you'll close your books up to 22% faster and free up your finance team to focus on strategic inventory decisions instead of expense report processing. Discover how Ramp can transform your inventory cost management.

Don't miss these

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°

“The ability to create flexible parameters, such as allowing bookings up to 25% above market rate, has been really good for us. Plus, having all the information within the same platform is really valuable.”

Caroline Hill

Assistant Controller, Sana Benefits