What is supplier performance management (SPM)? A quick guide

- What is supplier performance management?

- SPM vs. supplier relationship management (SRM)

- Why is supplier performance management important?

- What are the benefits of supplier performance management?

- Challenges in implementing supplier performance management

- Risks of poor supplier performance management

- The supplier performance management process

- Best practices for effective supplier performance management

- How to implement supplier performance management in your business

- Enhance your procurement and supplier management process with Ramp

Supplier performance management is a systematic approach to measuring, analyzing, and improving supplier performance to ensure they meet your business's requirements and expectations. By monitoring supplier activities, you can identify potential issues early, optimize procurement processes, and build more resilient supply networks.

In this guide, we'll cover why SPM is important, its benefits and challenges, and how to implement it in your business.

What is supplier performance management?

Supplier performance management

Supplier performance management (SPM) is the structured process of evaluating, measuring, and managing supplier activities against predetermined standards and expectations.

It involves collecting data on supplier performance, analyzing trends, and implementing improvement strategies to ensure suppliers consistently meet or exceed requirements.

SPM creates accountability within supplier relationships and connects to broader procurement and supply chain management. When properly implemented, it ensures that suppliers meet their contractual obligations, quality standards, and delivery schedules.

This alignment supports business objectives by reducing supply disruptions, controlling costs, and maintaining product quality. The data you gather through SPM also informs sourcing decisions, contract negotiations, and risk management strategies, creating a more resilient and efficient supply chain.

SPM vs. supplier relationship management (SRM)

Supplier performance management and supplier relationship management (SRM) serve different but complementary functions within your supplier management framework.

SPM focuses on measuring and evaluating supplier performance against specific metrics and standards. In contrast, SRM concentrates on developing and maintaining productive, collaborative relationships with suppliers to create long-term strategic value.

SPM and SRM differ in a few other key ways:

- SPM: Deals with tactical, measurable aspects of supplier interactions. Tracks metrics like on-time delivery percentages, defect rates, and response times to ensure suppliers meet operational requirements.

- SRM: Takes a more strategic approach. Focuses on building trust, improving communication, and fostering collaboration to create mutual value beyond transactional exchanges.

Here's how SPM and SRM work together to strengthen the supply chain:

- With SPM, you might track a supplier's monthly defect rate and issue corrective action requests when quality falls below agreed standards

- With SRM, you could establish a joint innovation program where your engineers collaborate with the supplier to develop new product features

- SPM might monitor a supplier's compliance with delivery schedules, while SRM could involve creating a vendor-managed inventory program that benefits both parties through improved forecasting and reduced stockouts

By integrating both SPM and SRM into your supplier management approach, you create a balanced strategy that measures performance while building relationships that drive long-term value and innovation.

Why is supplier performance management important?

Supplier performance management creates visibility and accountability throughout the supply chain, which is essential for business success.

Effective SPM ensures operational consistency by maintaining reliable access to quality materials and services when you need them. It helps control costs through data-driven negotiations and reduces waste from supplier errors.

In addition, supplier performance management helps identify and address supply chain risks before they affect business operations, protecting both production schedules and customer relationships.

Without monitoring supplier performance, the business is vulnerable to quality issues, delivery disruptions, and unnecessary costs that can hurt profitability and market position.

What are the benefits of supplier performance management?

Implementing effective supplier performance management helps your company reduce risks, manage costs, maintain compliance, and foster ongoing improvements with your supplier partners.

In detail, effective SPM programs offer several key benefits:

- Risk mitigation: By tracking supplier performance, you can spot potential problems before they become major disruptions. You can also avoid production delays, quality issues, and compliance problems that might affect your operations and reputation.

- Cost control: Ongoing performance monitoring helps identify inefficiencies that drive up costs. By tracking metrics like defect rates, on-time delivery, and invoice accuracy, you can negotiate better contract terms based on actual performance data.

- Compliance management: Systematic supplier monitoring ensures adherence to quality standards, safety regulations, and industry-specific requirements. This reduces the risk of violations that could lead to fines, recalls, or reputational damage.

- Continuous improvement: Strong SPM practices create an environment where performance data fuels supplier development, collaborative problem-solving, and innovation. Regular performance reviews provide opportunities to identify improvement areas.

SPM's benefits highlight why investing in supplier performance management makes good business sense. With strong supplier performance management practices, your business can build more valuable, resilient supplier relationships.

Challenges in implementing supplier performance management

Both technical limitations and organizational resistance can complicate SPM initiatives, requiring thoughtful planning and change management strategies.

- Data management issues: You may see poor data quality from manual entry errors, difficulty integrating information from other systems (ERP, procurement), and limited analytical capabilities to turn raw data into actionable insights

- Supplier resistance: Your suppliers may hesitate to participate due to concerns about transparency revealing weaknesses or fears that you'll use data punitively rather than constructively

- Resource constraints: You might underestimate the investment required to implement and maintain an SPM program, including budget for technology solutions, staff time for monitoring and analysis, and training resources to build necessary skills

Addressing challenges deliberately through strategic planning, clear communication with suppliers, and appropriate resource allocation will help ensure the SPM program delivers its intended benefits.

Risks of poor supplier performance management

When you neglect supplier performance management, you expose the business to operational, financial, and reputational risks that can impact the business's competitiveness and profitability.

Here are some of the risks of poor supplier performance management:

- Quality problems: Defective materials or components may enter production, resulting in finished products that fail to meet customer expectations. This can lead to damage to both the bottom line and brand reputation.

- Supply chain disruptions: Late deliveries, incomplete shipments, or sudden supplier capacity issues can halt production lines, causing costly downtime and damaged customer relationships

- Cost inefficiencies: You may incur expedited shipping charges to compensate for late deliveries, higher inventory carrying costs to buffer against unreliable suppliers, or premium prices for last-minute alternative sourcing

By investing in solid SPM practices, you can protect the business's operations, finances, and reputation while maintaining strong customer relationships.

The supplier performance management process

A structured, consistent supplier performance management process creates transparency and accountability that benefits both you and your suppliers. By establishing clear expectations and measurement processes, you can objectively evaluate performance and drive continuous improvement.

1. Set clear performance indicators

Identify metrics that directly impact business objectives, and ensure your targets are quantifiable, time-bound, and relevant to both operational needs and supplier capabilities. Balance ambitious goals with realistic expectations based on industry standards and supplier capacity.

2. Use supplier scorecards

Use standardized supplier scorecards to track and communicate performance, including metrics like delivery performance, quality, responsiveness, and cost management. Update scorecards regularly and share them with suppliers to maintain transparency and focus improvement efforts.

3. Conduct regular performance reviews

Schedule recurring review meetings with suppliers based on their strategic importance and performance trends, and hold monthly check-ins for critical partners and quarterly reviews for stable relationships. Analyze data to identify patterns, discuss improvement opportunities, and document action items with assigned responsibilities and deadlines.

4. Leverage tools for efficiency

Implement ready-to-use supplier scorecard templates as well as performance dashboards for real-time visibility into supplier metrics with automated data collection and visualization. Use integrated SPM modules to automate the process from data collection to reporting and action planning within procurement software tools.

Following a supplier performance management process creates a clear framework that guides suppliers toward high performance while strengthening partnerships through objective measurement and collaborative improvement.

Best practices for effective supplier performance management

Effective supplier performance management requires a proactive, structured approach that anticipates issues rather than simply reacting to problems after they occur. To excel at SPM, build systems and practices that create visibility, accountability, and continuous improvement throughout your supplier relationships.

Here are some key best practices for supplier performance management:

- Proactive monitoring: This helps identify potential issues before they affect operations. Implement regular data collection and analysis to flag performance trends and exceptions early.

- Open communication: This is the foundation for productive supplier relationships and performance improvement. Establish regular check-in schedules tailored to supplier importance and performance status.

- Digital tools: These streamline SPM processes and improve consistency. Invest in leading procurement software that automates data collection, generates real-time performance dashboards, and sends timely alerts when metrics fall outside acceptable ranges.

Implementing best practices will allow you to create a performance management approach that drives supplier excellence while building collaborative partnerships focused on mutual growth and continuous improvement.

How to implement supplier performance management in your business

Supplier performance management strengthens business operations by ensuring reliable access to quality materials and services while controlling costs and mitigating risks.

Effective SPM programs support organizational growth by creating scalable supplier relationships, improving operational efficiency through reduced disruptions and waste, and building resilience by identifying and addressing vulnerabilities before they affect the business.

Here's how to implement SPM in your business:

- Assess current practices: Conduct an internal audit of existing processes, tools, and metrics to establish a baseline and pinpoint gaps. Interview key stakeholders from procurement, operations, and quality departments to understand pain points and priorities.

- Define clear goals and KPIs: Identify supplier behaviors and outcomes that drive value for the business. Develop measurable indicators for each priority area, ensuring they reflect both operational requirements and supplier capabilities.

- Evaluate and implement tools: Consider integration capabilities, user-friendliness, scalability, and total cost of ownership. Start with solutions that address the most critical needs, then expand functionality as the program matures.

- Train stakeholders and create accountability: Provide role-specific training for procurement teams on performance monitoring, data analysis, and supplier development. Educate managers on contributing feedback and using SPM data in decision-making.

- Implement a regular review cycle: Schedule quarterly assessments of program effectiveness, examining both process and outcome metrics. Gather feedback from internal users and suppliers to identify friction points and improvement opportunities.

Implementing SPM builds a program that aligns supplier capabilities with your business needs while creating measurable improvements in quality, cost, and operational reliability.

Enhance your procurement and supplier management process with Ramp

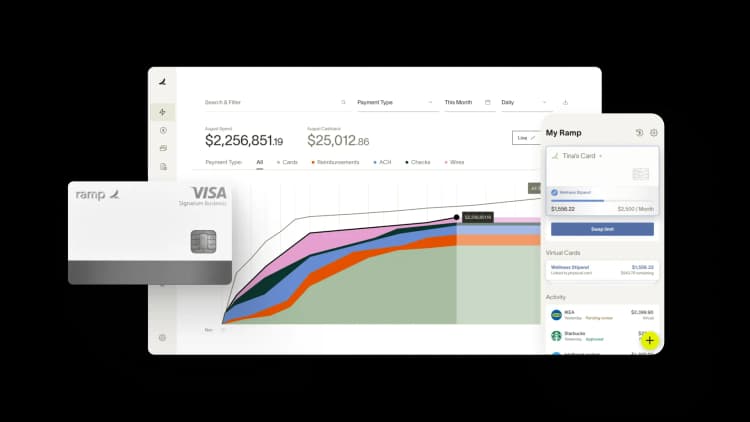

Procurement software streamlines supplier performance management by centralizing data collection, analysis, and reporting in one accessible platform. These digital solutions can automate scorecard generation, track KPIs in real time, and provide actionable insights through customizable dashboards.

Ramp elevates your supplier performance management process through intelligent spend analysis and comprehensive vendor management capabilities. Automated approval workflows and real-time expense tracking ensure compliance with supplier agreements while our customizable reporting features let you monitor key metrics that matter most to your business.

Ramp also offers:

- Seamless integration: Connect Ramp with your ERP and finance systems to unify supplier data and eliminate manual work

- Streamlined workflows: Automate repetitive tasks such as order creation, approvals, and invoice processing, accelerating the entire procurement cycle

- Enhanced financial control: See real-time tracking of spending and budgets, ensuring complete transparency and improved fiscal management

Explore how Ramp's procurement software can streamline your procurement process from beginning to end.

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Compared to our previous vendor, Ramp gave us true transaction-level granularity, making it possible for me to audit thousands of transactions in record time.”

Lisa Norris

Director of Compliance & Privacy Officer, ABB Optical

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°