- What is cost analysis?

- Cost analysis types

- Cost analysis key components

- How to perform a cost analysis: 7-step process

- Detailed step-by-step cost analysis example

- Cost analysis benefits

- Cost analysis tools and software

- 5 common challenges and solutions

- Real-world applications and examples

- ROI example: Value of cost analysis

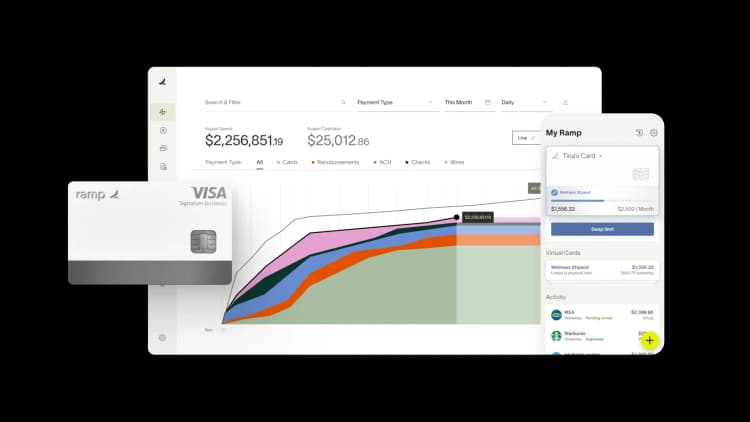

- How Ramp enables more accurate cost analysis

Cost analysis is the process of identifying, measuring, and forecasting all costs tied to a product, service, or decision so you can understand its true financial impact. It helps you compare options based on the full picture, not just obvious line items, whether you’re pricing a product, evaluating a project, or deciding whether to build in-house or buy a tool.

By breaking costs into clear categories and modeling how they change over time, cost analysis supports more accurate budgets, profitability forecasts, and investment decisions.

What is cost analysis?

Cost analysis is a structured way to determine the total cost of ownership or delivery for a product, service, initiative, or decision. That includes the costs you can easily trace, like materials and labor, plus the costs that sit in the background, such as overhead, tooling, implementation time, and ongoing support.

The core purpose is simple: calculate the actual total cost so you can compare options, set budgets, forecast profitability, and avoid surprises.

Let’s say you’re deciding whether to build a feature in-house or buy a tool. The subscription price might be easy to compare. Still, the real decision depends on implementation hours, ongoing admin time, training, security reviews, and the opportunity cost of pulling engineers away from other priorities.

Cost analysis vs. cost-benefit analysis

Cost analysis answers the question: What will this cost? Cost-benefit analysis answers a different one: Is it worth it?

In a cost-benefit analysis, you still estimate costs, but you also quantify benefits such as revenue, savings, risk reduction, and time saved. You then compare those benefits to total costs to determine whether the net outcome justifies the decision.

Cost analysis vs. price analysis

Price analysis focuses on the price tag. It helps you determine whether a vendor’s quote is reasonable compared to the market. Cost analysis focuses on your spend reality, or the total cost to implement, operate, and support a decision over time. Price analysis can inform cost analysis, but it rarely tells you the whole story on its own.

How cost analysis supports financial planning

Cost analysis connects day-to-day spending to big-picture planning:

- Improves budgeting by surfacing full cost drivers, not just the obvious ones

- Supports decision-making by making tradeoffs visible

- Strengthens forecasting by linking costs to volume, timelines, and capacity constraints

- Aligns cost accounting, how you report costs, with cost control, how you manage them

Cost analysis types

Cost analysis isn’t a single method. The right approach depends on what decision you’re making, how far into the future you need to look, and how precise your analysis needs to be.

Teams often combine multiple methods. For example, you might use activity-based costing to understand internal delivery costs, run a break-even analysis to test sales volume assumptions, and apply a lifecycle view to account for long-term maintenance and renewal costs.

In addition to the methods below, teams may also reference cost-effectiveness analysis, which compares options that achieve the same outcome to identify the lowest-cost option, and cost-feasibility analysis, which evaluates whether a project is affordable within budget and resource constraints.

Cost-benefit analysis

Cost-benefit analysis (CBA) compares expected costs to expected benefits, ideally in the same units, usually dollars. The output is often a net benefit, a benefit-cost ratio, or a recommendation based on which option produces the best return.

Use CBA when costs alone don’t tell the full story. It’s especially useful for decisions that trade money for time, risk reduction, compliance, customer experience, or operational resilience.

Assume you’re considering a $60,000 annual automation tool:

- Expected benefits: 12 hours per week saved across the finance team

- If fully loaded labor cost averages $70 per hour, the annual labor value is 12 * 52 * $70 = $43,680

- If you also expect fewer late fees and duplicate payments worth $25,000 per year, total benefit is $68,680

Net benefit = $68,680 − $60,000 = $8,680

That result highlights where to pressure-test assumptions, such as adoption risk, sustainability of time savings, and alternative options with higher upside.

Break-even analysis

Break-even analysis shows when a decision pays for itself by identifying the point where total revenue equals total costs. It’s commonly used for pricing decisions, product launches, and capacity planning.

Example:

- Fixed monthly costs: $50,000 (tooling, salaries, rent allocation)

- Variable cost per unit: $12 (materials, shipping)

- Selling price per unit: $32

- Contribution margin per unit = $32 − $12 = $20

Break-even point = Fixed costs / Contribution margin

Break-even point = $50,000 / $20 = 2,500 units

Break-even analysis forces you to separate fixed versus variable costs and test whether your volume assumptions are realistic.

Activity-based costing

Activity-based costing (ABC) assigns costs based on the activities that drive them, rather than spreading overhead evenly. It’s most useful when overhead is significant, processes vary by product or customer, or you need to understand which activities are actually consuming time and money.

ABC helps answer questions like:

- Which customer segments cost the most to support?

- Which product lines are profitable once you include operational load?

- Which internal workflows are driving disproportionate overhead?

Lifecycle cost analysis

Lifecycle cost analysis (LCCA) evaluates costs over the full life of an asset, system, or decision, not just the upfront purchase. In facilities and capital planning, LCCA typically includes acquisition, operation, maintenance, and end-of-life costs.

Use LCCA when a lower upfront cost could create higher long-term expenses, such as equipment purchases, fleet decisions, large software platforms, or multi-year vendor contracts.

A practical LCCA includes:

- Upfront costs: Purchase, implementation, setup

- Operating costs: Energy, labor, consumables, licenses

- Maintenance costs: Repairs, support, upgrades

- End-of-life costs: Disposal, replacement, contract exit, migration

If you’re comparing options over multiple years, discounting for the time value of money becomes important. Lifecycle cost frameworks commonly apply discount rates to compare long-term costs on an equivalent basis.

Cost analysis key components

A strong cost analysis breaks costs into categories you can defend, update, and explain. You’re not just adding numbers. You’re building a model you can reuse as decisions, volumes, and assumptions change.

Direct costs

Direct costs are expenses you can trace directly to a product, service, job, or project. Common examples include materials, project-specific labor, and subcontractor charges tied to a specific deliverable.

Examples:

- Manufacturing: Raw materials and assembly labor

- Services: Billable contractor hours

- Projects: Implementation consultants or hardware purchased for the initiative

Assume the following:

- A pilot run requires 800 units of material at $7.50 per unit, so direct materials cost = 800 * $7.50 = $6,000

- Labor is 120 hours at $45 per hour, so direct labor = 120 * $45 = $5,400

Total direct costs = $6,000 + $5,400 = $11,400

Indirect costs

Indirect costs support work but don’t tie neatly to a single product or project. These include overhead and administrative expenses such as facilities, IT, finance operations, shared tools, and leadership time.

You still need to allocate indirect costs, or your total cost will be understated.

Common allocation methods include:

- Direct labor hours: Useful when labor time drives overhead, which is common in services

- Direct costs or spend-based allocation: Effective when overhead scales with purchasing volume or workload

- Activity drivers: Appropriate when you can measure workload drivers like tickets, invoices, or shipments

- Flat percentage rate: A practical starting point when detailed allocation isn’t feasible

Fixed vs. variable costs

Fixed costs don’t change with output in the short term, while variable costs increase as volume rises.

Fixed costs include salaries, base software subscriptions, rent, and insurance. Variable costs include materials per unit, shipping per order, and payment processing per transaction.

How you classify costs matters. Misclassifying fixed and variable expenses can distort break-even points and profitability assumptions.

Opportunity costs

Opportunity cost is the value of the next best alternative you give up when you choose one option over another.

These costs rarely appear in your general ledger, but they affect real outcomes. Assigning senior engineers to a custom build may delay a revenue-driving feature, reduce reliability work, or push out a launch window.

Even when precise estimates aren’t possible, explicitly naming the tradeoff and estimating a reasonable range improves decision quality.

How to perform a cost analysis: 7-step process

Cost analysis works best when it’s repeatable. This seven-step process applies to projects, product decisions, and vendor evaluations, and it scales from quick back-of-the-envelope estimates to more detailed models.

Step 1: Define the scope

Start by clearly defining what you’re analyzing and why. Are you evaluating a one-time project, an ongoing service, or a multi-year investment?

Set boundaries to keep the analysis focused:

- Time horizon, such as three months, 12 months, or three years

- Cost categories included

- What the output needs to support, such as a decision, budget approval, or pricing model

Be explicit about what’s excluded. If you’re not modeling churn risk, implementation delays, or adoption uncertainty, state that upfront.

Step 2: Identify all cost categories

Before assigning numbers, make sure you’ve captured every relevant cost category. Missing categories early almost always lead to understated totals and flawed conclusions later.

A simple framework might include:

- Upfront costs: Purchase price, setup fees, implementation, training

- Operating costs: Labor time, tools, hosting, ongoing vendor fees

- Support and compliance costs: Security reviews, audits, approvals, policy updates

- Change costs: Rework, integrations, process redesign

- End-of-life costs: Vendor contract termination, migration, disposal

Step 3: Gather cost data

Populate each category with the best data available. Start with verifiable sources such as general ledger records, vendor invoices, contracts, and payroll data to establish defensible baselines.

For future or uncertain costs, use projections informed by comparable projects, operating metrics, or historical outcomes. When estimates are unavoidable, document assumptions clearly and use ranges instead of single-point estimates to reflect uncertainty.

Step 4: Calculate direct costs

Calculate direct costs using clear formulas and documented assumptions so the math can be reviewed and repeated.

Common pitfalls to avoid:

- Using list prices instead of contracted or discounted rates

- Underestimating internal labor tied to implementation, training, and administration

- Forgetting one-time costs such as data migration, integration work, or change management

Step 5: Allocate indirect costs

Choose an allocation method that reflects how overhead is actually consumed and apply it consistently.

Best practices include:

- Using cost drivers that reflect causality

- Separating overhead pools when activities differ meaningfully

- Documenting allocation rates and review cadence

Indirect cost allocation

If you need a defensible starting point for early-stage analysis, a flat overhead rate can work initially, as long as you apply it consistently and refine it as better data becomes available.

Step 6: Consider time value of money

When costs and savings occur over time, timing matters. A dollar today is not equivalent to a dollar several years from now.

Net present value (NPV) converts future cash flows into today’s dollars using a discount rate. In cost analysis, NPV allows you to compare options with different timing profiles on an equivalent basis and avoid distorting long-term decisions.

Step 7: Analyze and interpret results

The final step is interpretation. Review total costs by category and identify which assumptions have the greatest impact on outcomes. Large swings tied to labor, adoption, or volume forecasts signal areas that deserve closer scrutiny.

Translate the analysis into a clear recommendation. Cost analysis should support a decision, whether that decision is to approve, delay, renegotiate, or reject an option.

Detailed step-by-step cost analysis example

Consider this scenario: You’re evaluating a new expense management workflow for a 120-person company and want to estimate the first-year total cost compared to the current manual process.

Assumptions:

- Tool subscription: $18 per user per month

- Implementation: $8,000 one-time

- Internal rollout effort: 60 hours across finance and IT at $75 per hour, fully loaded

- Ongoing administration: 6 hours per week at $60 per hour

- Indirect overhead allocation: 10% of direct internal labor

- Current-state cost: 14 hours per week of manual work at $60 per hour, plus $9,000 per year in late fees and reimbursement errors

Step 1: Define scope

The scope is a first-year analysis of the new workflow, including subscription fees, implementation, internal labor, ongoing administration, and allocated overhead.

Step 2: Identify cost categories

Relevant categories include subscription costs, implementation fees, internal rollout labor, ongoing administration, and indirect overhead.

Step 3: Gather data

Inputs come from the vendor quote, current headcount, internal time estimates, and historical data on late fees and reimbursement errors.

Step 4: Calculate direct costs

- Subscription: 120 * $18 * 12 = $25,920

- Implementation: $8,000

- Internal rollout labor: 60 * $75 = $4,500

- Ongoing administration labor: 6 * 52 * $60 = $18,720

Direct costs = $25,920 + $8,000 + $4,500 + $18,720 = $57,140

Step 5: Allocate indirect costs

Indirect overhead = 10% * (Internal rollout labor + Ongoing administration labor)

Indirect overhead = 10% * ($4,500 + $18,720) = 10% * $23,220 = $2,322

Step 6: Consider time value of money

Discounting is not required here because most costs occur within a 12-month period.

Step 7: Interpret results

Estimated first-year total cost = $57,140 + $2,322 = $59,462

Now estimate the current-state annual cost:

- Manual labor: 14 * 52 * $60 = $43,680

- Errors and late fees: $9,000

- Current total: $52,680

At face value, the new workflow costs about $6,782 more in year one. However, if the tool reduces manual time from 14 hours per week to 5 hours per week, savings change the outcome:

- Labor saved: 9 * 52 * $60 = $28,080

- Avoided fees and errors: $9,000

- Total savings = $37,080

Net year-one impact = Savings − Incremental cost difference

Net year-one impact = $37,080 − $6,782 = $30,298

This example shows why cost analysis matters. The decision hinges on a few assumptions, such as time saved and error reduction, and the model makes those drivers explicit.

Cost analysis benefits

Cost analysis pays off when it moves decisions from intuition to evidence. By making costs explicit and comparable, it helps teams plan more accurately, allocate resources more effectively, and reduce financial risk.

Improved budget accuracy and financial planning

Cost analysis improves budget accuracy by forcing you to account for the full cost structure of a decision before committing funds. Instead of relying on high-level estimates or historical averages, you break costs into direct, indirect, fixed, and variable components that better reflect how spending actually behaves.

Over time, this discipline strengthens financial planning. Budgets become more predictable because assumptions are explicit, overhead is intentionally allocated, and recurring costs surface earlier.

Better project profitability predictions

Profitability forecasts often fall short because they exclude internal labor, overhead, or downstream support costs. Cost analysis ties revenue expectations to the full cost of delivery, not just external spend or marginal expenses.

When applied consistently, cost analysis clarifies which projects, products, or clients generate sustainable margins. That helps you prioritize work that supports long-term profitability instead of growth that quietly erodes financial performance.

Enhanced decision-making for investments

Cost analysis replaces intuition-driven investment decisions with structured evaluation. By comparing alternatives using consistent cost categories and time horizons, you reduce bias and improve decision quality.

This approach is especially valuable when tradeoffs aren’t obvious. Cost analysis highlights differences in risk, scalability, and long-term financial impact, helping leaders choose options that align with strategic goals.

Identification of cost-saving opportunities

Cost analysis often reveals savings in places teams overlook:

- Process bottlenecks: Quantifying time costs helps you prioritize automation where it has the most impact

- Vendor consolidation: Total cost modeling surfaces overlapping tools, duplicate renewals, and fragmented contracts

- Policies and controls: When approvals, reimbursements, or rework drive real labor costs, improving controls can unlock measurable savings

Risk mitigation through comprehensive cost understanding

Understanding costs in detail reduces financial risk by making potential overruns and constraints visible early. When cost analysis includes sensitivity testing, teams can anticipate how changes in volume, staffing, or timelines affect outcomes.

This visibility supports contingency planning and reduces the likelihood of projects stalling due to underestimated operational or funding constraints.

Support for pricing strategies

Pricing decisions depend on knowing your cost floor. Cost analysis provides that foundation by clarifying fully loaded unit economics, including overhead and support costs that pricing models often overlook.

With accurate cost data, you can evaluate discounts, promotions, and contract terms with confidence, understanding how pricing changes affect break-even volume, margins, and capacity utilization.

Cost analysis tools and software

The best cost analysis tool is the one you’ll actually use and maintain. For many teams, cost analysis starts simple and becomes more sophisticated as decisions, data volume, and organizational complexity increase.

A practical rule of thumb is to begin with a repeatable template and move to specialized tools only when scale or complexity demands it.

Spreadsheet templates

Spreadsheets are often the starting point for cost analysis because they’re flexible, transparent, and easy to adapt. Excel and Google Sheets allow you to:

- Model scenarios quickly

- Document assumptions clearly

- Share results with stakeholders without specialized training

For early-stage analyses or one-off decisions, a well-structured spreadsheet can provide decision-grade accuracy without unnecessary complexity.

Common templates include:

- Project cost breakdown templates

- Break-even analysis templates

- Activity-based costing driver tables

- Lifecycle cost templates with year-by-year costs and discounting

When choosing a template, prioritize clarity over complexity. A simple model that gets used is more valuable than a perfect model that no one trusts.

Specialized software solutions

Dedicated cost analysis and planning tools become useful when teams need multi-scenario forecasting, consistent allocation logic, version control, or automated reporting for leadership.

Look for tools that integrate with your expense management system so actual spending data flows into your models. This connection helps align cost analysis with cost control by keeping assumptions grounded in real transactions.

Visualization also matters. Dashboards that show cost by category, variance versus plan, and unit economics help decision-makers act without living in spreadsheets.

5 common challenges and solutions

Cost analysis breaks down when it becomes either too messy to trust or too complicated to maintain. These are the most common challenges teams run into and how to address them.

1. Incomplete or inaccurate data collection

Incomplete data is one of the biggest barriers to effective cost analysis. Start with verifiable sources, clearly label estimates, and use ranges when precision isn’t possible. Transparency matters more than perfection, especially when assumptions are documented and revisited over time.

2. Difficulty in allocating indirect costs

Indirect costs are challenging because they don’t tie cleanly to a single product or project. Consistent allocation methods based on realistic cost drivers help reduce distortion. Even a simplified approach is better than ignoring overhead entirely, as long as it’s applied consistently and updated periodically.

3. Accounting for intangible costs and benefits

Factors like risk reduction, time savings, and customer experience are hard to quantify, but excluding them weakens decision-making. When exact values aren’t possible, use ranges, proxy measures such as hours saved, or scenario comparisons, and document assumptions clearly.

4. Keeping analysis current with changing costs

Costs change as vendors update pricing, teams scale, and expense workflows evolve. Setting a regular review cadence and linking analysis to live expense and invoice data helps keep models relevant as conditions change.

5. Balancing detail with practicality

Overly detailed models slow decisions and discourage adoption. The goal is decision-grade accuracy, not mathematical perfection. Focus detail on the largest cost drivers and simplify areas where incremental precision won’t change the outcome.

Real-world applications and examples

Cost analysis looks different by industry, but the pattern is consistent: define scope, capture direct and indirect costs, model timing, and compare options.

Manufacturing cost analysis

In manufacturing, cost analysis is often used to determine true unit economics. A manufacturer might calculate unit cost based on direct materials and labor, then allocate overhead such as maintenance, utilities, and supervision to understand fully loaded costs.

This approach is especially important for make-versus-buy decisions. A vendor’s price is only part of the equation. Procurement overhead, quality risk, logistics, inventory carrying costs, and the opportunity cost of internal capacity all affect the real outcome.

Project cost analysis

Project cost analysis commonly breaks down when teams budget only for external spend and overlook internal time, rework, and ongoing support.

A more accurate model includes implementation hours, change management, training, and maintenance. When internal labor is treated as a real cost driver, teams can prioritize projects based on value per constrained hour, not just headline budgets.

Service industry cost analysis

Service firms use cost analysis to understand fully loaded delivery costs per engagement, including billable hours, non-billable support, management oversight, and tools.

Activity-based costing models are particularly useful here. They reveal which client types or engagement scopes generate the most rework and support load, even when revenue appears healthy.

A real-world cost savings example

Cost analysis can lead to measurable savings when organizations use it to identify and act on cost drivers.

In a 2020 GAO review of a contractor cost-savings program at the National Nuclear Security Administration, GAO reported that the agency verified about $515 million in cumulative cost savings through fiscal year 2018 and estimated roughly $2.9 billion in savings over 10 years.

The takeaway applies beyond the public sector. When teams systematically measure costs, track savings initiatives, and validate results, efficiency translates into real dollars.

ROI example: Value of cost analysis

Running a cost analysis takes time, but the return can far exceed the effort when it helps you avoid hidden costs or negotiate better outcomes.

Assume a vendor evaluation requires:

- 20 hours of finance time at $70 per hour = $1,400

- 8 hours of engineering review at $110 per hour = $880

Total analysis cost = $1,400 + $880 = $2,280

The analysis uncovers:

- A hidden implementation requirement that would have added $18,000 in contractor fees

- An overlap with an existing tool, enabling a $6,000 annual reduction through renegotiation

Total first-year value = $18,000 + $6,000 = $24,000

Return on investment (ROI) = (Value − Cost) / Cost

ROI = ($24,000 − $2,280) / $2,280 ≈ 9.53, or 953%

Cost analysis isn’t overhead. It’s a lever that turns better information into measurable financial impact.

How Ramp enables more accurate cost analysis

Analyzing costs across your organization can be time consuming. You may be reviewing expense reports from multiple departments, reconciling disconnected spreadsheets, and struggling to see which costs actually drive value versus those that quietly erode margins.

Ramp’s expense management software helps turn cost analysis into an ongoing, data-backed process instead of a one-time exercise. The platform automatically categorizes transactions across your organization, giving you clear visibility into spending by department, vendor, and category. Instead of waiting for month-end reports, you can monitor cost drivers as they change.

That visibility supports more accurate cost analysis. When you can see real spending patterns, you can validate assumptions, identify inefficiencies earlier, and update models with actual data rather than estimates.

Ramp also helps reduce the manual work that makes cost analysis hard to sustain. Automated controls, policy enforcement, and real-time alerts help prevent waste before it happens, while clean, structured data makes it easier to analyze trends over time.

Whether you’re running a break-even analysis, evaluating a new vendor, or refining pricing assumptions, Ramp gives you the foundation to understand true costs and act on them. To see how it works in practice, explore an interactive demo.

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Compared to our previous vendor, Ramp gave us true transaction-level granularity, making it possible for me to audit thousands of transactions in record time.”

Lisa Norris

Director of Compliance & Privacy Officer, ABB Optical

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°