- What is a goods receipt?

- The role of a good receipt in the purchase order process

- Understanding 3-way matching with goods receipts

- Goods receipts in accounts payable and invoice matching

- Best practices for managing goods receipts

- From goods received to invoice paid—with fewer errors

- Choose Ramp Bill Pay to save your team time and money

As a business owner, you likely have shipments arriving frequently while managing other tasks. It might be easy to quickly sign for a shipment and deal with it later. But if you do, you might be missing a crucial step: a goods receipt.

A goods receipt verifies that what you ordered actually arrived—and in acceptable condition—before approvals move forward or updating your inventory. It’s the handoff between receiving and finance in the broader procurement and purchase-to-pay cycle.

Understanding what a goods receipt is, why it matters, how it works, and best practices for managing them is crucial to protecting your finances, improving inventory accuracy, and laying the foundation for reliable AP processes, like 3-way matching.

What is a goods receipt?

A goods receipt (GR), also known as a goods receipt note (GRN), is a formal record that confirms your business has received items from a supplier. It's typically created once the goods arrive and are inspected for quantity, quality, and condition against the purchase order (PO).

Beyond documenting delivery, the goods receipt note acts as a control point between procurement and accounts payable. It serves as one of the three documents used in 3-way matching, alongside the PO and supplier invoice, to ensure payment is only issued for goods that were properly received.

You may also hear a goods receipt referred to as a receipt of goods. Often, these terms are interchangeable, but the concept of receipt of goods more broadly refers to the physical act of receiving goods, rather than the documentation in a goods receipt.

Goods receipts and the procurement process

The goods receipt is created when a shipment arrives at the receiving location. You first check the supplier’s packing slip or delivery note, then inspect the items for the correct quantities and expected qualities. After that inspection, you create the goods receipt to record what was delivered and any discrepancies. In the procurement workflow, the goods receipt comes after delivery but before invoice verification and payment.

Key components of a goods receipt document

A goods receipt typically includes:

- Date of receipt

- Goods receipt number

- Purchase order number

- Supplier information (name, address, contact)

- Item descriptions and quantities

- Unit costs

- Total value

- Condition of goods

- Names of receivers and approvers with signatures

Sample goods receipt

| Field | Example |

|---|---|

| Goods receipt number | GRN-2025-0041 |

| Date of receipt | Oct 15, 2025 |

| PO number | PO-3102 |

| Supplier | Apex Paper Co. |

| Item description | A4 paper reams |

| Quantity received | 100 |

| Condition | Excellent |

| Received by | J. Taylor |

| Approved by | M. Chen |

Who creates a goods receipt?

Warehouse staff, receiving clerks, or procurement personnel typically issue the goods receipt. After delivery, they inspect the shipment against the PO, record results in the system, and route for approval. Supervisors or quality inspectors then review and approve the record.

Many teams use an enterprise resource planning (ERP) or warehouse management system with barcode scans and system entries to capture quantities, conditions, and discrepancies in real time. This supportsinventory accuracy and downstream invoice matching.

Goods receipt vs. other procurement documents

A goods receipt is just one document in the procurement process that also includes purchase orders, invoices, and delivery notes. Each serves a purpose in the process. These are the key differences:

| Document | Purpose | Created by | Used by |

|---|---|---|---|

| Goods receipt | Confirms physical receipt of shipments | Warehouse/receiving | Inventory, accounting, procurement |

| Purchase order | Initiates the buying process | Procurement | Vendor, receiving, finance |

| Invoice | Requests payment | Vendor | Accounts payable, finance |

| Delivery note | Confirms what was shipped | Vendor | Receiving |

The role of a good receipt in the purchase order process

The goods receipt is a critical piece in the purchase order process. The purchase order initiates the procurement process, and then the goods receipt note serves as both the physical and administrative confirmation that goods have been received accurately and in good condition.

Let’s review the full purchase order lifecycle, particularly focusing on where the goods receipt fits in.

From purchase order to goods receipt

The receipt of goods process helps ensure shipments are accurate, in good condition, and recorded before inventory and financial systems are updated. While workflows vary by business, core steps include:

- Purchase order creation: Procurement issues a purchase order that defines items, quantities, pricing, and timing

- Vendor acknowledgement: The vendor accepts the PO and prepares the shipment with a delivery note

- Goods receipt: On arrival, items are unloaded and checked against the PO and delivery note. You record quantities, SKUs, and any discrepancies on the goods receipt

- Payment processing: Once confirmed, finance processes the supplier invoice. AP completes a 3-way match of the PO, goods receipt, and invoice before releasing payment.

Let’s look at an example to illustrate the process. A large bookstore chain creates a PO to purchase 1,000 copies of a current bestseller. The procurement team submits the PO to the book distributor, who acknowledges the order and prepares the shipment.

The shipment arrives in the receiving area at the bookstore, and upon inspection, there are only 950 copies of the book, all in sellable quality. Both facts are noted on the goods receipt. When the finance manager sees that the order was shorted, they contact the distributor to amend the invoice to reflect the actual quantity received. Once that is resolved, payment is submitted for the 950 books.

Handling discrepancies

Discrepancies between the delivery note and the goods receipt are common. Typical issues include:

- Incorrect quantities

- Quality issues

- Incorrect items

- Damaged goods

Document issues on the goods receipt, take photos of damage, and notify procurement immediately. For rejected items, create a return document and, if needed, a debit memo. Update inventory and follow up with the vendor on replacements or a corrected shipment.

Impact on the overall procurement process

When discrepancies aren’t managed, you risk payment delays, inventory inaccuracies, financial discrepancies, and future audit issues. Prompt, accurate goods receipts help you avoid these downstream problems.

Understanding 3-way matching with goods receipts

The 3-way matching process is an accounts payable control that only approves payment when the purchase order, goods receipt, and supplier invoice agree. Without a timely, accurate goods receipt, AP teams delay payments or risk paying for items that weren’t received as ordered.

Recent data from Settle found that 47% of purchase orders had inconsistencies compared with invoices, representing more than $12 million in discrepancies—exactly the kind of errors 3-way matching is designed to prevent.

The three documents in 3-way matching

- Purchase order: The reference for what was ordered, including item descriptions, quantities, prices, and terms

- Goods receipt: The confirmation of what was received, with quantities, conditions, delivery date, and PO reference

- Invoice: The bill requesting payment, with billed quantities, prices, total due, due date, and payment terms

Benefits of 3-way matching

- Fraud prevention: Reduces the risk of paying for duplicate, missing, or damaged items

- Error reduction: Catches data entry or billing errors before payment

- Better vendor relationships: Fewer disputes thanks to transparent documentation

- Improved cash flow management: Payments only flow for verified purchases

Goods receipts in accounts payable and invoice matching

In the accounts payable process, the goods receipt bridges inventory and payment. AP teams use it to verify that goods were received before approving invoices as part of 3-way matching. Without that documentation, payment workflows can’t move forward.

Invoice matching process

Invoice matching verifies that payment requests align with purchase orders and goods receipts. Here’s how the process typically works:

- Invoice submission: The vendor sends an invoice for payment

- Verification: AP compares the invoice with the purchase order and goods receipt using 3-way matching

- Discrepancy resolution: Mismatches are flagged for review and resolved before approval

- Approval and payment: Once verified, AP approves and processes the payment

If the documents don’t match, the invoice may be rejected or returned to the vendor. Some organizations set tolerance rules to prevent bottlenecks, such as:

- Quantity tolerance: Up to 5% difference between quantity received and invoiced

- Price tolerance: Up to $10 variance between the PO and invoice

- Date tolerance: Accepting invoice dates that align within a defined range of the goods receipt

Automation in goods receipt and invoice processing

Creating goods receipts by hand can be tedious and error-prone. Digitizing them eliminates paper trails, updates inventory in real time, and gives procurement and AP instant access to records.

Modern AP software, such as Ramp, SAP Concur, and QuickBooks, streamlines this process by:

- Aligning PO and goods receipt data automatically

- Matching invoice line items to received goods

- Creating custom approval workflows

- Flagging issues for human review

Automation reduces manual work, speeds up approvals, and improves accuracy. According to Bosch, automating goods receipts can increase productivity by 30%.

Best practices for managing goods receipts

A well-run goods receipt process ensures accuracy in payments and inventory records. By standardizing how receipts are created, entered, and reviewed, you can drive faster cycle times and better alignment across procurement, receiving, and finance.

Tips for improving goods receipt management

- Set strict SLAs for entry: Require goods receipts to be logged promptly to keep inventory and payment timelines in sync

- Use barcode or RFID scanning: Eliminate manual entry, speed up verification, and prevent mismatched quantities or SKUs

- Create standard exception workflows: Route damaged, shorted, or incorrect items through a documented resolution process

- Integrate ERP or AP systems: Centralize receiving, procurement, and accounts payable for real-time matching and faster resolution

- Designate a structured receiving area: Separate inspection, staging, and storage zones to prevent mix-ups during high-volume periods

Common challenges in handling goods receipts

Even efficient teams run into challenges that disrupt inventory and delay approvals. Common issues include:

- Missing or delayed receipts: When entries aren’t made promptly, inventory falls out of sync and invoices may be paid without verification. Use mobile tools for quicker check-ins and automatic sync.

- Discrepancies with the PO: Mismatched SKUs or quantities trigger manual reviews and payment delays. Implement automated 3-way matching to catch issues early.

- Damaged or defective goods: Poor handling can slow operations and require rework or credit negotiations. Train staff on damage protocols and photo documentation.

- Manual documentation: Paper or spreadsheets increase data errors and reduce visibility. Move to digital templates for standardization.

- Poor storage coordination: Disorganized receiving docks lead to misplaced goods and slower throughput. Label incoming, stocked, and damaged zones for better tracking.

Creating an effective goods receipt process

An efficient goods receipt process starts with standard operating procedures. Consistency reduces errors and keeps teams aligned. Focus on these fundamentals:

- Verify every shipment against its PO

- Inspect goods upon arrival

- Log discrepancies immediately with photos

- Get sign-off approval for all deliveries

- Update inventory systems once verification is complete

Training and quality control measures

Processes only work when teams understand and follow them. Invest in training that covers reading POs and invoices, using scanners, managing discrepancies, and warehouse flow. Reinforce accuracy through quality checks such as:

- Photo documentation for any discrepancies

- Isolating damaged shipments from sellable stock

- Random sampling inspections of inventory batches

- Continuous feedback between warehouse and procurement teams

Technology and tools

Moving from paper to digital is one of the most effective ways to improve goods receipt accuracy and scalability. Digital receipts integrate with ERP and accounting systems to deliver:

- Seamless 3-way matching

- Automated discrepancy alerts

- Real-time inventory and billing updates

- Easy tracking for AP audits

For busy warehouse teams, mobile apps with barcode scanning, photo capture, and offline functionality ensure updates even when connectivity is limited

From goods received to invoice paid—with fewer errors

The receipt of goods is where purchasing meets accountability. It’s the point where your team confirms what’s been delivered—and the trigger for everything that follows. Matching that delivery to a purchase order and invoice shouldn’t take hours of manual review.

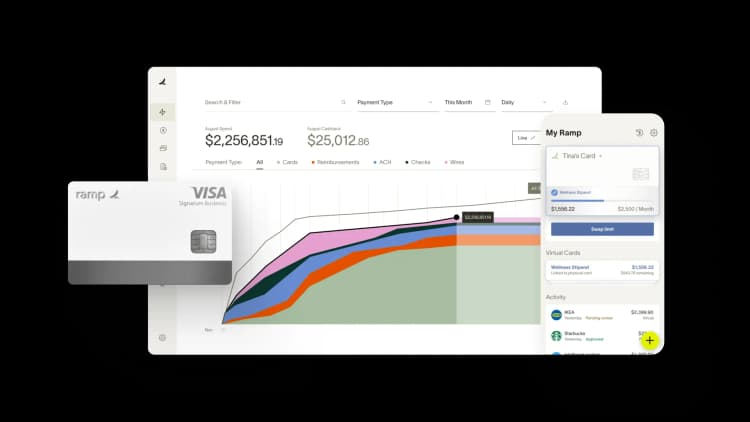

Ramp Bill Pay is an autonomous accounts payable platform where four AI agents make your AP process touchless. They manage invoice coding, spot payment fraud, build approval summaries, and process vendor payments through cards—no manual work needed. OCR achieves 99% accuracy on line-item data, while invoice processing runs 2.4x faster than older AP systems1.

Use Ramp Bill Pay as your standalone AP system, or connect it with Ramp’s corporate cards, expense reimbursements, and procurement workflows for unified financial oversight. Even up to 95% of companies report stronger payables visibility after moving to Ramp2.

With Ramp, you can:

- Automate 3-way matching: Match invoices to purchase orders and goods receipts, and flag discrepancies before they delay approvals or payments

- Streamline invoice intake: Use AI-powered OCR invoice processing to extract line-item details, apply suggested GL codes, and reduce manual work

- Keep systems in sync: Sync POs, receipts, and payments with NetSuite, QuickBooks, and more to eliminate double entry and maintain accuracy

- Use intelligent invoice capture: Optical character recognition technology reads and digitizes invoice content with 99% accuracy

- Set custom approval workflows: Configure authorization chains that route invoices according to department hierarchy, spending thresholds, and vendor relationships

- Get real-time invoice tracking: View the current status of every invoice from initial receipt to final disbursement

- Set roles and permissions: Establish access controls that maintain proper segregation of financial responsibilities across your organization

- Schedule recurring bills: Schedule automatic payment execution for subscription services and regular vendor invoices

- Send batch payments: Execute multiple vendor disbursements simultaneously rather than processing them individually

Choose Ramp Bill Pay to save your team time and money

Ramp Bill Pay redefines what modern AP should look like: accurate, autonomous, touchless, and fast. Over 2,100 verified G2 reviews give Ramp a 4.8-star rating, and users consistently rank it as one of the easiest AP platforms to use. Finance leaders turn to Ramp to cut out busywork, prevent costly mistakes, and finish month-end close faster.

You don't have to use Ramp's other products to get value from Bill Pay—it's a complete AP solution on its own. But if you're looking to manage bill payments, card spending, employee expenses, and procurement all in one system, Ramp also makes that possible.

From intake to approval to payment, Ramp helps you close the loop so every delivery, match, and payment happens with fewer errors and less effort.

AP should be simple. With Ramp Bill Pay, it is. Try Ramp Bill Pay.

1. Based on Ramp’s customer survey collected in May’25

2. Based on Ramp's customer survey collected in May’25

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°

“The ability to create flexible parameters, such as allowing bookings up to 25% above market rate, has been really good for us. Plus, having all the information within the same platform is really valuable.”

Caroline Hill

Assistant Controller, Sana Benefits