- What is marginal cost?

- Practical examples of marginal cost

- Why does marginal cost matter in business?

- Key takeaways for marginal costs

- Putting it all together

- Track variable costs in real time with Ramp's automated spend categorization

This post is from Ramp's contributor network—a group of professionals with deep experience in accounting, finance, strategy, startups, and more.

Interested in joining? Sign up here.

Understanding marginal cost is essential for small business owners looking to make smart pricing decisions, manage production, and scale their profitability. Whether you're launching a new product or growing your business, it's critical to know how each additional unit impacts your profits.

Marginal cost is the cost of producing one more unit of a product or service. It's not the average production cost, but the cost you incur to produce a single additional unit. Knowing your marginal cost helps you make informed decisions about pricing, hiring, inventory planning, and investments.

What is marginal cost?

Marginal cost is the cost of producing one additional unit of a product or service. It's not the average cost of production, but the cost you incur to produce just one more unit or output.

This concept is key because it helps you determine your optimal production level, whether you're making a product or providing a service. When your marginal cost is lower than your selling price, you're in a position to profit from making more. But when it starts to exceed your selling price, it may be time to scale back or reassess your operations.

Marginal cost is used across industries. Manufacturers track it to set production levels. Service providers use it to assess the impact of hiring additional staff. And retailers use it to decide when to restock and at what quantity.

Marginal cost formula

The marginal cost formula is:

Marginal cost = Change in total cost / Change in quantity

Let's break down the calculation:

- Change in total cost is the difference in cost when you produce more units.

- Change in quantity is the increase in the number of units produced.

This formula isolates the cost of producing just one more unit of output. It's often calculated over small increases to stay accurate. If your production scale changes dramatically, your fixed and variable costs can shift in ways that distort the result.

Practical examples of marginal cost

Example 1: A small bakery in Boston

Imagine a bakery that makes 100 loaves of sourdough bread each day. The total cost of ingredients, labor, and utilities for those 100 loaves is $200. If the bakery increases production to 101 loaves, and total costs rise to $202, then:

Marginal cost = ($202 – $200) / (101 – 100) = $2

That means the cost of producing the 101st loaf is $2. If the bakery sells each loaf for $3, they're profiting on that additional unit. But if overtime labor kicks in at a higher rate, or if additional equipment is needed to meet demand, marginal cost could jump unexpectedly, changing the marginal cost curve.

Example 2: A custom furniture shop

Consider a furniture maker who builds handcrafted tables. The first 10 tables cost $4,000 total. The next 5 cost an additional $2,500 due to higher material costs and more labor hours.

Marginal cost = ($6,500 – $4,000) / (15 – 10) = $500

Each additional table costs $500 to produce. If the tables sell for $800 each, the shop owner needs to assess whether that $300 margin is worth the additional work and time. This is where marginal cost drives decision-making.

Why does marginal cost matter in business?

Marginal cost plays a central role in many financial decisions for both production and service-based businesses. Here are some of the ways it shows up:

1. Pricing strategy

When marginal cost is lower than the market price, producing more makes sense. As you scale, marginal cost can increase due to factors like more materials, labor, and space. At some point, your profit per unit may shrink or disappear.

That's why it's dangerous to rely only on average costs when setting your prices. You could be underestimating how expensive it becomes to scale, a common pitfall for small businesses.

2. Break-even analysis

Knowing your marginal cost helps you figure out how many units you need to sell to cover fixed costs. It's essential for understanding how long it takes to recover from an investment or to justify the cost of new equipment.

3. Capacity planning

If you're running at full capacity and thinking about expanding, marginal cost tells you whether the additional output justifies the cost of growth. It also helps identify the point of diminishing returns, when additional production starts to cost more than it earns.

4. Profit optimization technique

Businesses that understand marginal cost can identify the most profitable level of output. Beyond that point, profits may drop even if revenue increases. The numbers can be deceiving if you're not looking closely.

Key takeaways for marginal costs

Marginal cost is the cost to produce one additional unit. It's not the same as average cost and should be evaluated separately.

The marginal cost formula is simple: change in total cost divided by change in quantity.

Whether you're baking bread, building tables, or selling a service, marginal cost helps determine whether producing more makes financial sense.

Marginal cost affects critical decisions from pricing to capacity planning, so knowing yours gives you a competitive edge.

Marginal cost can shift based on factors like labor rates, material costs, and scale efficiencies or inefficiencies.

Putting it all together

Marginal cost isn't just a number on a spreadsheet. It's a decision-making tool to use as your business grows and scales. It helps you avoid unprofitable growth, spot hidden inefficiencies, and find the most productive scale of operations.

Small shifts in marginal cost can create big changes in profitability. By tracking it regularly and understanding the forces behind it, you put yourself in a position to make smarter, faster, and more confident decisions about your business's future.

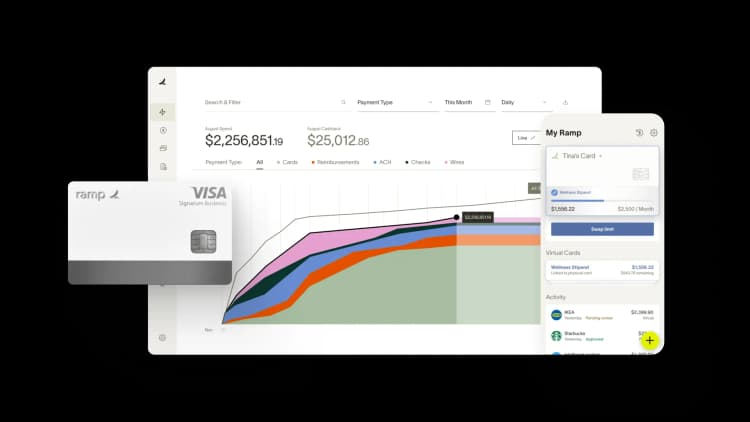

Track variable costs in real time with Ramp's automated spend categorization

Calculating marginal cost requires accurate tracking of variable expenses like materials, labor, and overhead. But when transactions are coded inconsistently, you're making pricing decisions on incomplete data. Ramp's AI-powered accounting software eliminates guesswork by coding every transaction automatically and consistently, so you always know your true variable costs.

Ramp learns your accounting patterns and codes transactions across all required fields as they post, applying the same logic to similar expenses every time. When you need to analyze marginal costs by product line, department, or project, Ramp's custom fields and tags let you segment spend however your business requires. You can track variable costs down to the transaction level and surface insights that inform smarter pricing and scaling decisions.

Here's how Ramp supports accurate marginal cost analysis:

- AI codes variable expenses consistently: Ramp applies your coding rules to every transaction in real-time, so materials, labor, and overhead land in the right accounts without manual review

- Segment costs with custom fields: Tag transactions by product, project, or cost center to track variable expenses at whatever level of detail your pricing models require

- Review spend with full context: Ramp surfaces receipts, approvals, and transaction details automatically, so you can verify variable costs and catch anomalies before they skew your calculations

- Export clean data instantly: Pull transaction-level reports filtered by any dimension to feed your marginal cost models with accurate, up-to-date information

Try a demo to see how Ramp gives you the clean, categorized data you need to calculate marginal costs with confidence.

Don't miss these

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°

“The ability to create flexible parameters, such as allowing bookings up to 25% above market rate, has been really good for us. Plus, having all the information within the same platform is really valuable.”

Caroline Hill

Assistant Controller, Sana Benefits