The construction procurement process: A beginner’s guide

- What is procurement in construction?

- Roles and responsibilities in construction procurement

- Construction procurement methods

- The construction procurement process: Step by step

- Challenges in construction procurement

- Best practices for managing construction procurement

- Simplify construction procurement with Ramp

Construction procurement is how you get the materials, services, and labor needed for construction projects. Contractors rely on efficient procurement to keep bids competitive and operations profitable. When done well, procurement ensures you have the right resources at the right time, price, and quality.

In this guide, we'll cover basic concepts, key roles, procurement methods, and the step-by-step process that leads to successful construction projects.

What is procurement in construction?

Construction procurement

Procurement in construction is the process of sourcing, buying, and managing all the materials, services, and contracts you need for construction projects.

This includes everything from basic building materials to specialized equipment and subcontractor services. Procurement connects project plans to actual execution. The main goals of construction procurement are to get resources delivered on time to prevent delays, maintain quality standards, keep costs within budget, and support project schedules with well-timed deliveries.

Meeting these goals requires careful planning throughout the project. Construction procurement goes beyond simple purchasing. It involves evaluating and selecting suppliers, managing contracts, complying with regulations, and coordinating logistics.

This approach requires specialized knowledge, not just buying skills. You need to balance immediate project needs with longer-term considerations like supplier relationships and market conditions.

What are the benefits of effective construction procurement?

Effective construction procurement creates significant advantages in several key areas that directly affect project success and profitability:

- Cost control: Good procurement directly impacts the bottom line by securing better pricing, preventing unnecessary purchases, and reducing waste

- Financial efficiency: Through strategic sourcing and bulk purchasing, you can save money while maintaining quality standards and keeping projects within budget

- Project efficiency: When you handle procurement well, materials and services arrive exactly when needed, preventing costly delays

- Timeline management: By aligning procurement with the project schedule, you keep momentum going and make the best use of resources, reducing downtime and completing projects faster

- Quality assurance: Good procurement includes thorough vendor screening, detailed material specifications, and quality control measures. These steps ensure everything meets your standards, reducing rework and potential failures.

- Risk mitigation: Proper planning helps identify and address supply chain risks before they affect the project

Construction procurement is a practical strategy that builds profitability, strengthens quality, and reduces delays while keeping your projects running smoothly from start to finish.

Roles and responsibilities in construction procurement

Effective procurement depends on a skilled team working together with clear responsibilities. Each person plays a specific part in the process, from planning and purchasing to delivery and implementation, to ensure successful outcomes.

- Project managers: Oversee the procurement strategy, making sure it aligns with project goals and timelines. They approve major purchases and solve procurement issues that could impact project delivery.

- Procurement managers: Develop purchasing strategies, manage supplier relationships, and lead the procurement team. They set policies, negotiate major contracts, and ensure everyone follows organizational standards.

- Estimators: Calculate how much material you'll need and what it will cost, providing crucial information for budgeting and bids. Their accuracy directly affects project profitability.

- Contract administrators: Handle the formal documentation, ensuring legal compliance and protecting your interests. They manage contract changes, monitor performance, and keep detailed records.

- Site supervisors: Coordinate deliveries, check quantities and quality when materials arrive, and tell the procurement team what's needed in the field. Their practical insights help prevent ordering mistakes and delivery problems.

Clear communication between all stakeholders is essential for successful procurement. When information flows freely between project managers, procurement specialists, and field personnel, they make better decisions and face fewer disruptions.

Construction procurement methods

The construction industry uses several procurement methods, each with different characteristics that affect how your project runs. Your choice of method impacts risk allocation, stakeholder collaboration, and project timeline. Choosing the right approach depends on the project's complexity, budget constraints, and priorities.

1. Design-bid-build

This is the traditional method where design and construction are separate. You first hire designers to create complete plans and specifications. Once designs are finished, contractors submit competitive bids based on these documents. You typically award the contract to the lowest qualified bidder.

This method clearly defines responsibilities and offers competitive pricing but can extend the project's timeline because design and construction happen one after the other. Design-bid-build works well for straightforward public projects with defined scopes and tight budgets.

2. Design-build

This method combines design and construction under a single contract, streamlining the process. You contract with one entity responsible for both design and construction services. This approach allows design and construction to happen at the same time, speeding up project delivery.

Design-build gives you more flexibility for changes during construction and typically reduces administrative burden. It transfers significant risk to the design-builder while encouraging collaboration between designers and constructors. It's good for complex projects with tight schedules, especially in the private sector where speed-to-market matters.

3. Construction management

This involves hiring a construction manager who provides professional management services throughout the project. Depending on the arrangement, the construction manager may act as an advisor (CM as agent) or take on risk for construction (CM at risk).

This method allows for early contractor involvement during design, providing input and more accurate cost estimates. Construction management provides flexibility in subcontractor selection and can accommodate fast-tracking. It works well for complex projects requiring specialized expertise and owner involvement in the construction process.

4. Integrated project delivery (IPD)

This is a collaborative approach where key project stakeholders join through a multiparty contract with shared risk and reward. This method emphasizes early involvement of all parties, collaborative decision-making, and open information sharing.

IPD typically uses target value design and lean construction principles to optimize outcomes. The procurement process focuses on selecting team members based on qualifications and collaborative potential rather than lowest price. IPD suits complex, innovative projects where stakeholder collaboration can drive value and where you prioritize lifecycle performance over initial cost.

Selecting the right construction procurement method depends on your specific project needs and goals, whether prioritizing cost certainty, speed, flexibility or collaboration.

The construction procurement process: Step by step

A well-executed procurement strategy ensures you get resources when needed, maintain quality standards, and control costs. This systematic approach helps you anticipate challenges and implement solutions before they affect the project.

- Plan: Establish clear objectives aligned with project goals, define the procurement scope, develop preliminary budgets, identify key stakeholders, and create a procurement timeline. Assess potential risks and determine which procurement methods work best for different parts of the project.

- Define specifications: Create clear, detailed specifications. Document precise requirements for materials, equipment, and services, including quality standards, performance criteria, quantities, and delivery timeframes.

- Solicit bids: Prepare and distribute request documents (RFPs, RFQs, or ITBs) to potential suppliers. Outline project requirements, submission guidelines, evaluation criteria, and contractual terms.

- Evaluate Bids: Evaluate technical capabilities, pricing, delivery schedules, and supplier qualifications to find the best options

- Select suppliers: Assess their financial stability, past performance, technical capabilities, and capacity to deliver. This may include checking references, visiting sites, and testing samples to verify supplier claims and reduce project risk.

- Contract suppliers: Negotiate terms, pricing structures, delivery schedules, and performance metrics. Clear contracts establish accountability and protect all parties by defining scope, quality requirements, payment terms, and how to resolve disputes.

- Track progress: Communicate with suppliers, monitor production, and coordinate logistics to prevent delays. For critical items, you might conduct factory inspections or require progress reports to verify quality and schedule adherence.

- Monitor performance: Verify material quality upon delivery, document any issues, and work with suppliers to resolve problems. This oversight ensures that procurement activities support project schedules and quality requirements while staying within budget.

- Manage contracts: Address changes, resolve disputes, and ensure all parties fulfill their obligations. This also includes processing payments, documenting communications, and maintaining comprehensive records of all procurement activities and decisions.

- Monitor compliance: Ensure adherence to building codes, safety regulations, environmental requirements, and labor laws. This includes verifying supplier certifications, obtaining necessary permits, and maintaining documentation to demonstrate compliance during inspections or audits.

- Close the contract: Finalize all payments, collect warranties and maintenance documentation, evaluate supplier performance, and archive procurement records. This final step provides valuable data for future projects and helps you continuously improve procurement practices.

While this framework provides a general structure, you can tailor procurement processes to your specific project needs. Larger, more complex projects may require more elaborate procedures, while smaller projects might streamline certain steps. The key is maintaining a systematic approach that ensures transparency, accountability, and alignment with project objectives.

Challenges in construction procurement

Construction procurement comes with unique challenges. It's necessary to constantly balance competing priorities of speed, cost, and quality while navigating a complex supply chain. These challenges can affect project outcomes if not properly addressed.

Managing lead times

This is one of the most persistent procurement challenges. Materials with extended manufacturing periods—such as custom steel fabrications or specialized mechanical equipment—can delay your critical path if not ordered well in advance. Approval processes for submittals and samples further complicate timelines, especially when multiple stakeholders must review and sign off.

To overcome these challenges, you can implement early procurement strategies for long-lead items, develop detailed procurement schedules aligned with construction sequencing, and establish streamlined approval workflows with clear accountability.

Cost control

This is a significant challenge, especially in volatile market conditions. Material price fluctuations, unexpected shortages, and scope changes can quickly erode your budget and create financial pressure. Inaccurate quantity takeoffs or incomplete specifications often lead to change orders and cost overruns during execution.

Effective strategies to control costs include implementing value engineering early in the process, securing price guarantees for volatile materials, developing contingency plans for high-risk items, and establishing clear change management procedures to control scope creep.

Ensuring material quality

This remains challenging throughout the procurement cycle. Substandard materials can compromise structural integrity, system performance, and aesthetics, leading to costly rework and potential liability issues. Verification is especially difficult with international sourcing or new suppliers without established track records.

To mitigate quality risks, implement comprehensive pre-qualification processes for suppliers, conduct factory inspections for critical components, require material certifications and test reports, and perform thorough quality checks upon delivery.

Supply chain disruptions

These pose increasing risks to construction projects. Global events, transportation bottlenecks, labor shortages, and supplier financial instability can all interrupt material flow at critical moments. These disruptions can cascade through project schedules, creating delays that impact multiple work fronts.

Effective mitigation strategies include developing relationships with multiple suppliers for critical materials, maintaining safety stock for essential items, and creating contingency plans that identify alternative sources or materials.

While construction procurement challenges are complex, proactive procurement management, strong supplier relationships, and adaptable strategies can minimize disruptions and deliver successful project outcomes within budget and timeline constraints.

Best practices for managing construction procurement

Implementing procurement best practices helps you deliver projects on time and within budget while maintaining high quality standards. Here's how:

- Develop a comprehensive procurement strategy: Involve procurement early during project planning to identify opportunities and risks before they impact execution. Define which procurement methods to use for different project components based on risk profiles, market conditions, and project requirements.

- Use technology and software solutions: Modern procurement software solutions centralize information, automate routine tasks, and provide real-time visibility into procurement status. E-procurement systems streamline supplier communication, bid management, and order processing while creating digital audit trails.

- Standardize processes and documentation: This reduces errors and improves consistency across projects. Well-designed procurement templates for RFPs, contracts, and purchase orders ensure you capture all necessary information while reducing preparation time.

- Cultivate strong supplier relationships: Strategic partnerships with key suppliers can provide you with preferential pricing, priority allocation during shortages, and enhanced service levels. Regular supplier performance reviews with constructive feedback help improve service quality over time.

- Measure and improve procurement performance: Establish key performance indicators (KPIs) for procurement activities to objectively measure success factors like cost savings, on-time delivery, quality compliance, and supplier performance

- Use digital tools: The best procurement software can provide end-to-end management of procurement activities. Data analytics tools help you identify spending patterns, negotiate better terms, and predict potential issues before they occur.

Following best practices strengthens your procurement function, creating meaningful improvements in project outcomes. The effort invested in refining your approach pays off through better cost control, smoother operations, and higher quality deliverables.

Simplify construction procurement with Ramp

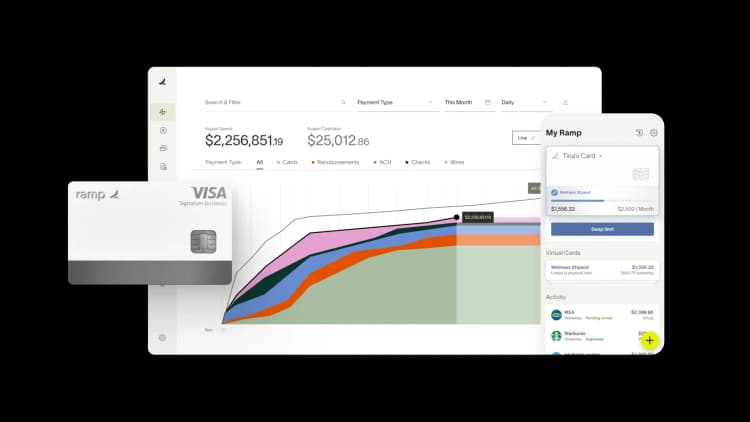

Construction teams manage high volumes of purchases, vendors, and documentation—often under tight deadlines and budgets. Ramp’s procurement software helps streamline this complexity by centralizing purchase orders, automating manual tasks, and giving teams real-time visibility into spend.

With Ramp, your team can create purchase orders, route them through custom approval chains, and track every dollar spent on materials, contractors, and services. Automated invoice matching reduces accounting workload and helps prevent duplicate payments or billing errors—keeping projects on track and under control.

Here’s more on how Ramp supports smarter construction procurement:

- Intake in an instant: Upload a contract, and Ramp’s AI auto-fills the request details

- Reduce risk: Prevent errors and fraud with automated three-way matching

- Get better pricing: Benchmark quotes against anonymized data from thousands of real transactions

- Integrate easily: Sync Ramp with your ERP and finance systems to centralize supplier data and eliminate rework

Discover how Ramp Procurement helps construction teams stay efficient and cost-effective—project after project.

“In the public sector, every hour and every dollar belongs to the taxpayer. We can't afford to waste either. Ramp ensures we don't.”

Carly Ching

Finance Specialist, City of Ketchum

“Compared to our previous vendor, Ramp gave us true transaction-level granularity, making it possible for me to audit thousands of transactions in record time.”

Lisa Norris

Director of Compliance & Privacy Officer, ABB Optical

“Ramp gives us one structured intake, one set of guardrails, and clean data end‑to‑end— that’s how we save 20 hours/month and buy back days at close.”

David Eckstein

CFO, Vanta

“Ramp is the only vendor that can service all of our employees across the globe in one unified system. They handle multiple currencies seamlessly, integrate with all of our accounting systems, and thanks to their customizable card and policy controls, we're compliant worldwide. ”

Brandon Zell

Chief Accounting Officer, Notion

“When our teams need something, they usually need it right away. The more time we can save doing all those tedious tasks, the more time we can dedicate to supporting our student-athletes.”

Sarah Harris

Secretary, The University of Tennessee Athletics Foundation, Inc.

“Ramp had everything we were looking for, and even things we weren't looking for. The policy aspects, that's something I never even dreamed of that a purchasing card program could handle.”

Doug Volesky

Director of Finance, City of Mount Vernon

“Switching from Brex to Ramp wasn't just a platform swap—it was a strategic upgrade that aligned with our mission to be agile, efficient, and financially savvy.”

Lily Liu

CEO, Piñata

“With Ramp, everything lives in one place. You can click into a vendor and see every transaction, invoice, and contract. That didn't exist in Zip. It's made approvals much faster because decision-makers aren't chasing down information—they have it all at their fingertips.”

Ryan Williams

Manager, Contract and Vendor Management, Advisor360°